Market Spotlight: Tailored Solutions for Global Hubs

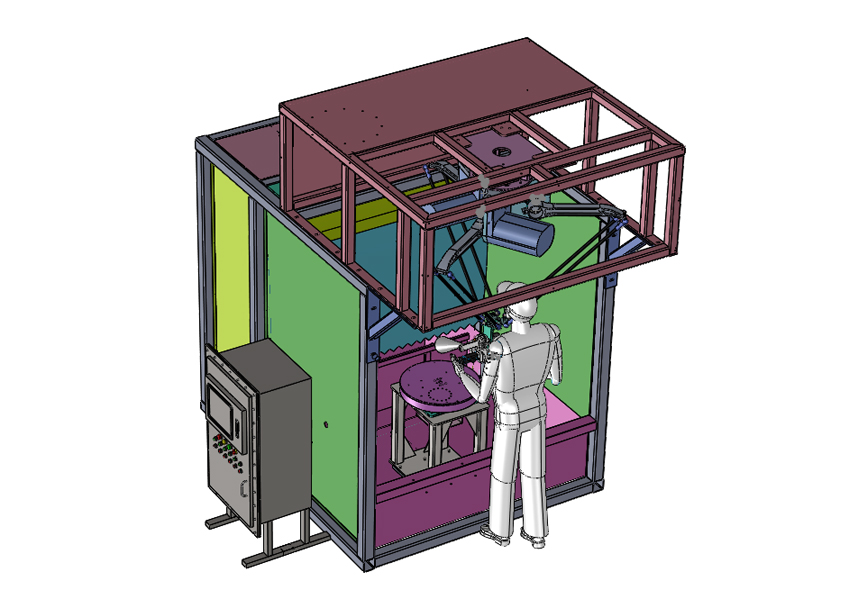

The "one-size-fits-all" approach to automation is dead. ZeroCodeSpray.com focuses on high-impact industries where the skill shortage is most severe.

Vietnam: Denim Finishing and Furniture Painting

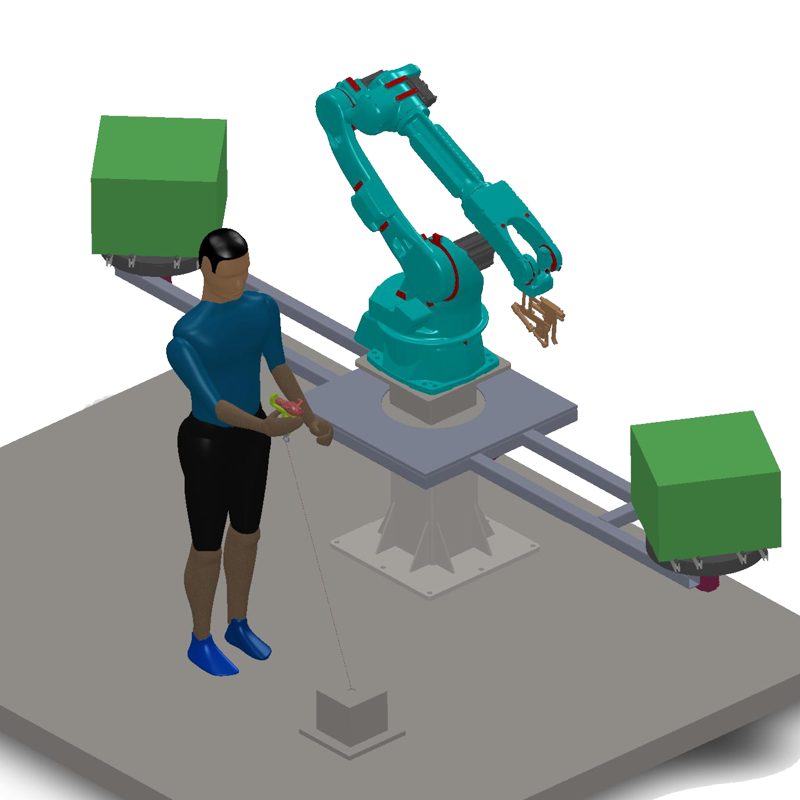

Vietnam has emerged as a powerhouse for global apparel and home decor. However, the Vietnam Denim Market is facing pressure to automate the "whiskering" and pigment spraying processes to meet environmental and labor standards. Our Zero-Code robots allow Vietnamese furniture and textile factories to automate overnight, ensuring that furniture painting remains consistent and high-quality without the need for expensive software engineers.

India: Electric Sensors and Ceramic Glazing

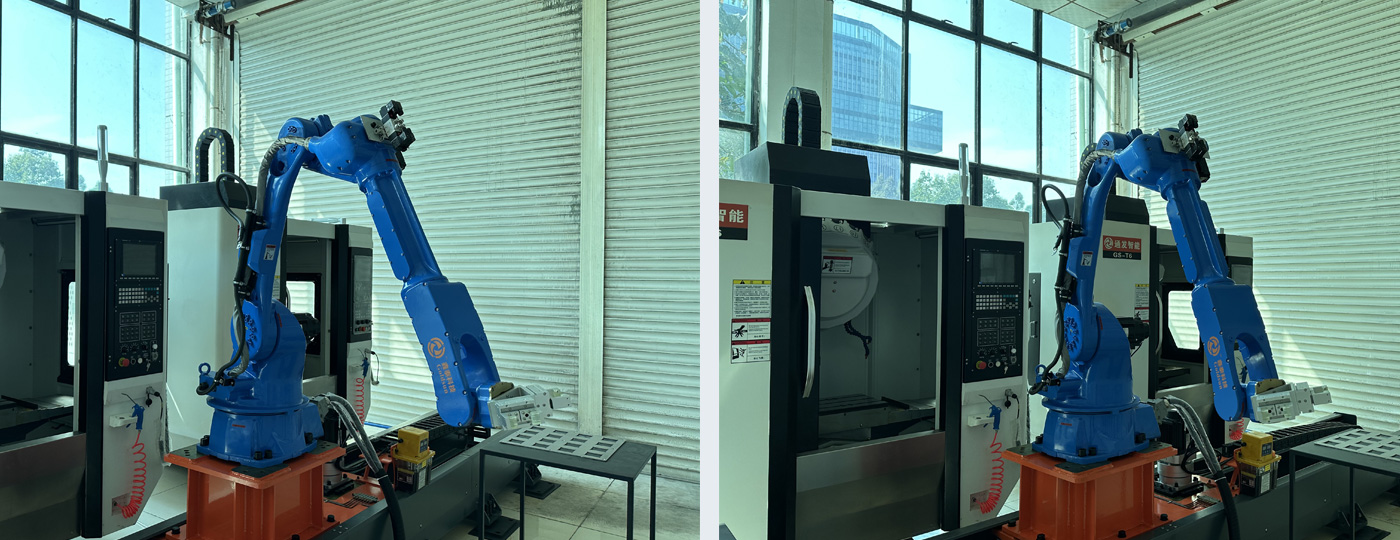

In India, the push for Ceramic glazing automation is skyrocketing as the region becomes a global hub for sanitary ware. Simultaneously, the manufacturing of Electric Sensors and Instrument Transformers (CT/VT) requires precision anti-corrosive coating. Our Drag-and-Teach spraying solutions are specifically engineered to handle the complex fins and bushings of electrical components, providing a level of dielectric integrity that manual spraying cannot guarantee.

The Bottom Line: Automate Today, See ROI by Next Year

Investment in automation is ultimately a financial decision. The high cost of third-party integrators and downtime for changeovers often kills the ROI of traditional robotics.

With our Code-Free workstations, the math is simple:

Zero Programming Costs: No need to hire or retain specialized robotics talent.

30% Less Material Waste: Precision fluid control reduces glaze and paint consumption.

Instant Changeovers: Switch product lines in 5 minutes, keeping the line moving.

As we tell our partners: "Automate today, see ROI by next year."

Meet Us Worldwide: Global Industrial Events

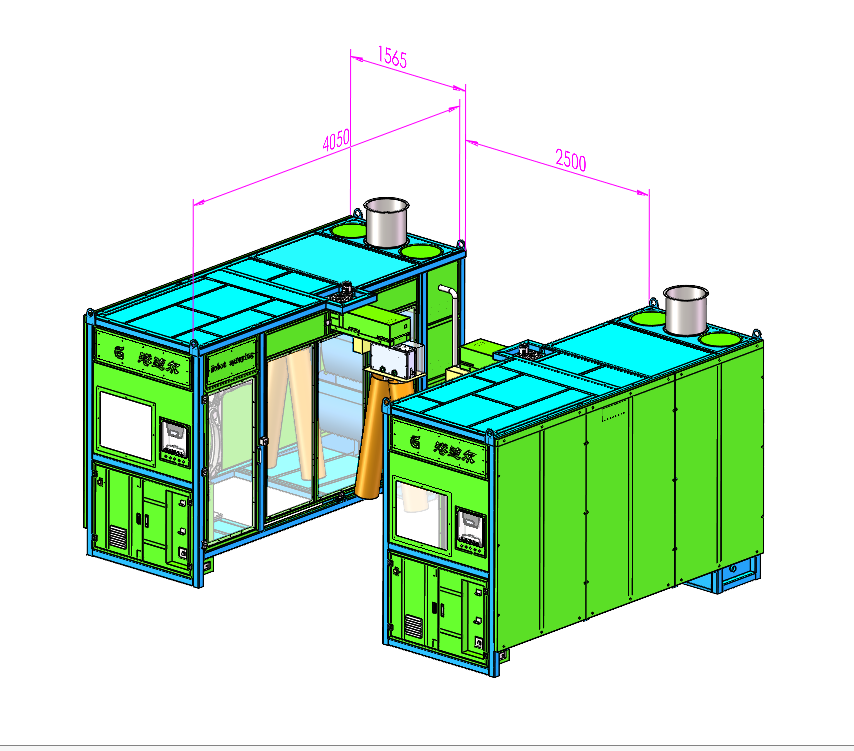

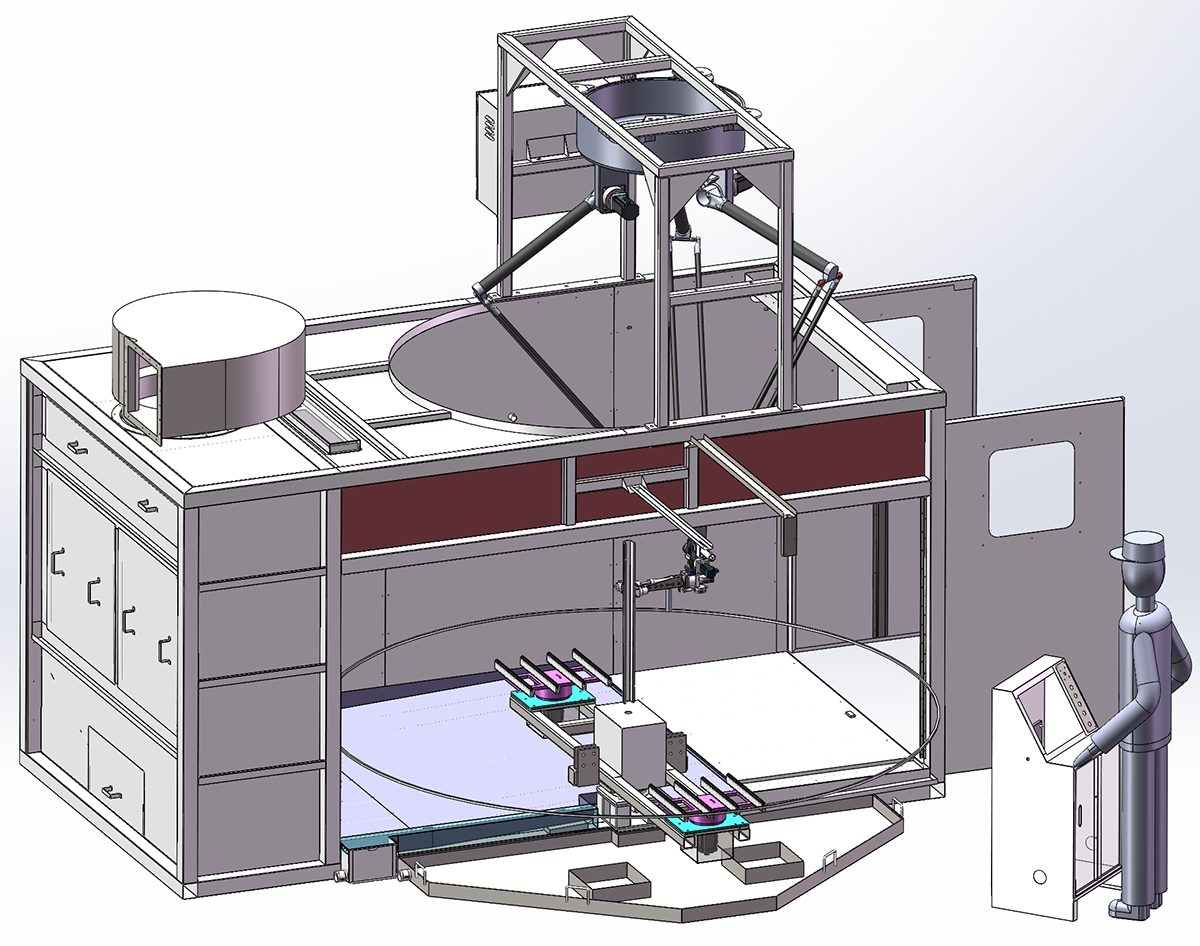

We are committed to bringing the code-free revolution to your doorstep. Join us at the world's premier industrial showcases to see our T2000 Workstation in action:

Europe: Look for us at Hannover Messe (Germany) for general industrial excellence and Tecna (Italy) for the latest in Ceramic Glazing Automation.

North America: Experience our high-speed finishing at FABTECH.

Emerging Markets: Visit our booths at the Vietnam Industrial Expo and IMTEX (India Machine Tool Exhibition) to discuss localized solutions for the Southeast Asian and Indian markets.

Conclusion: Future-Proof Your Factory

The era of complex coding is over. Whether you are coating high-voltage sensors in Bangalore or spraying denim in Ho Chi Minh City, ZeroCodeSpray.com provides the intuitive, rugged, and precise tools you need to stay competitive.

Stop fighting the labor crisis and start leading the market.

VisitZeroCodeSpray.comtoday for a free process evaluation and a live demo of the world’s most accessible Spraying Robot.