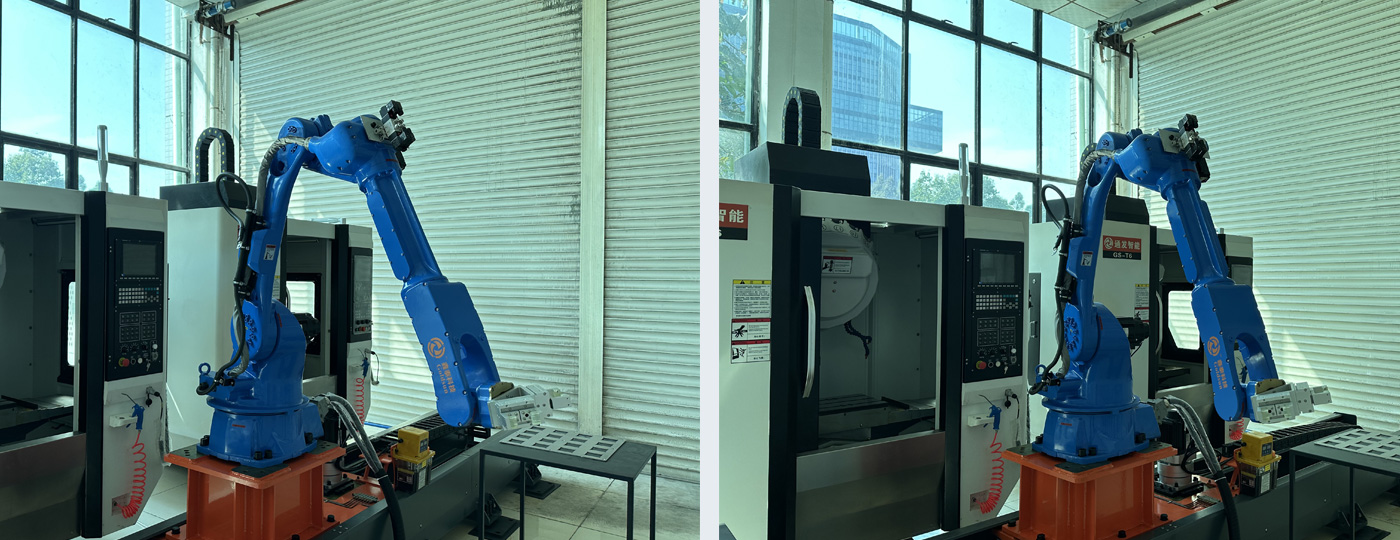

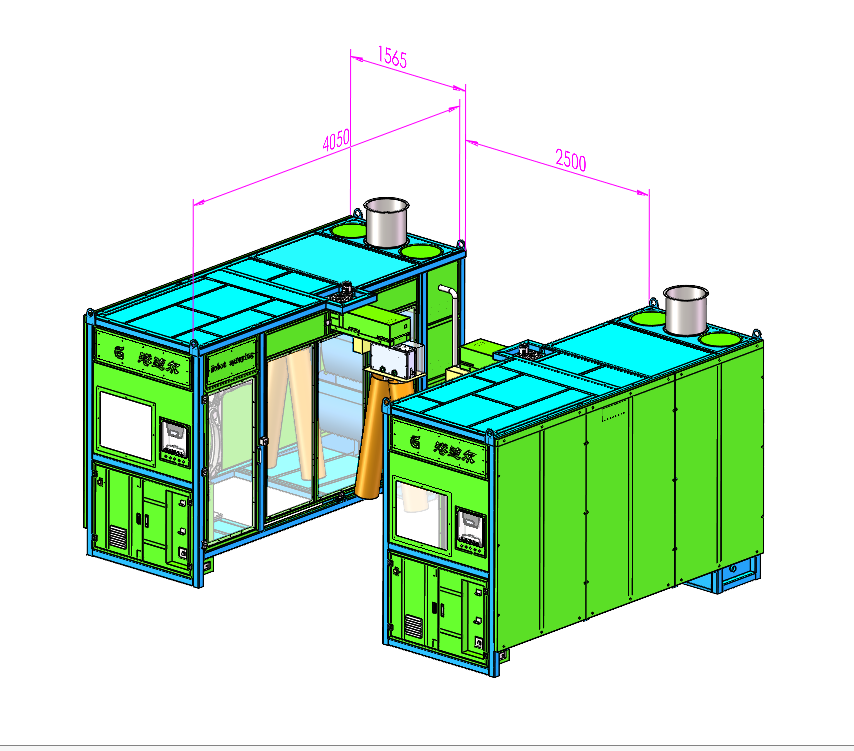

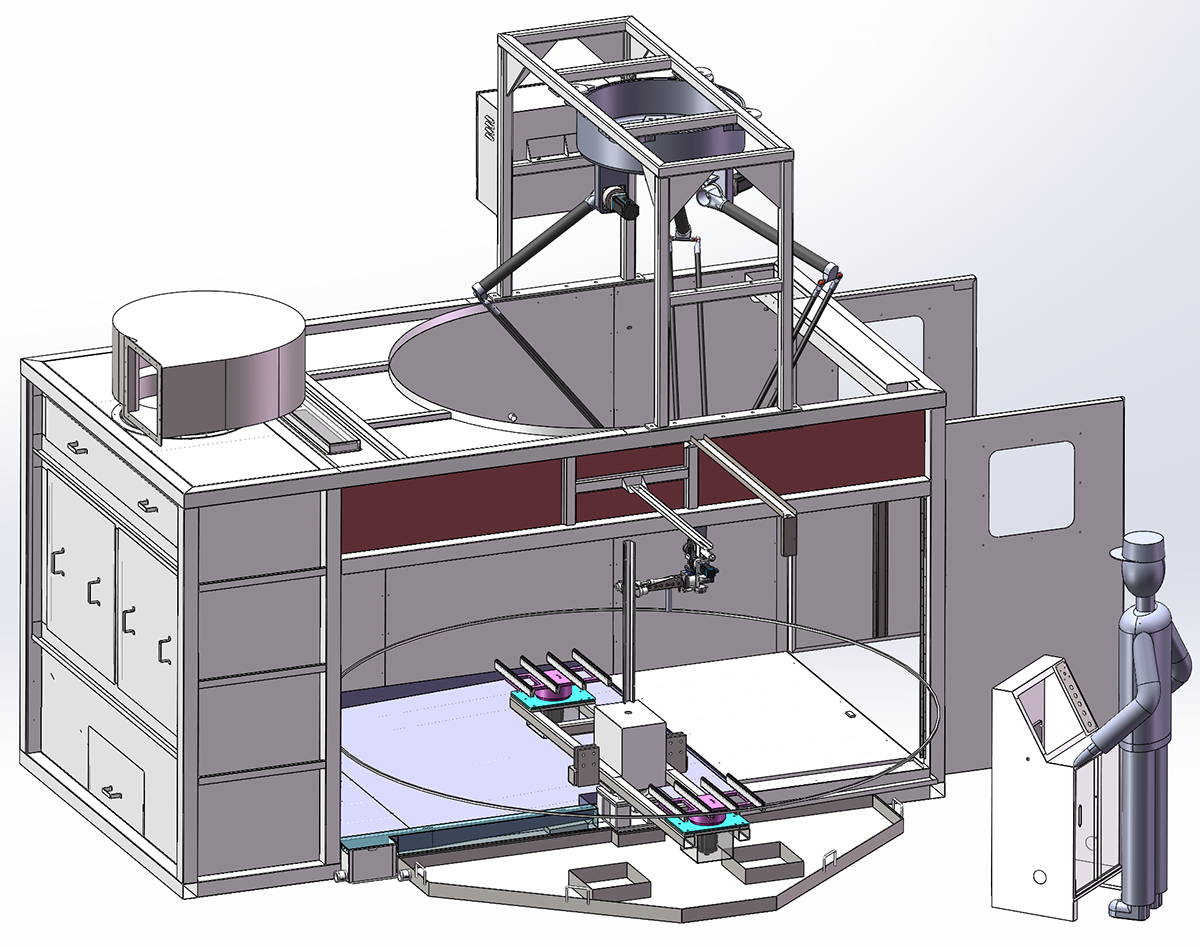

The T2000 Spraying Workstation is a self-developed system by Xinke Smart, with autonomous innovation spanning the mechanical structure, controller, and software algorithms. It is widely applicable for the spraying of fiberglass bathtubs and the glazing of ceramic sanitary ware.

This product is the largest parallel-series hybrid structure robot in China, and also the country's first original creation of its kind. The system is based on a real-time Linux operating system, utilizing the EtherCAT industrial bus for communication.

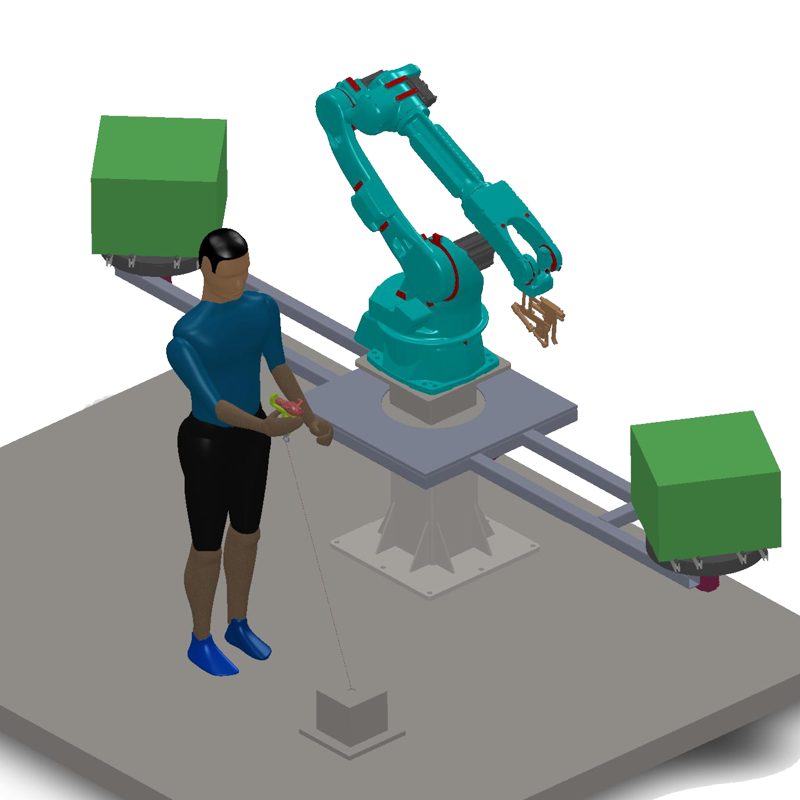

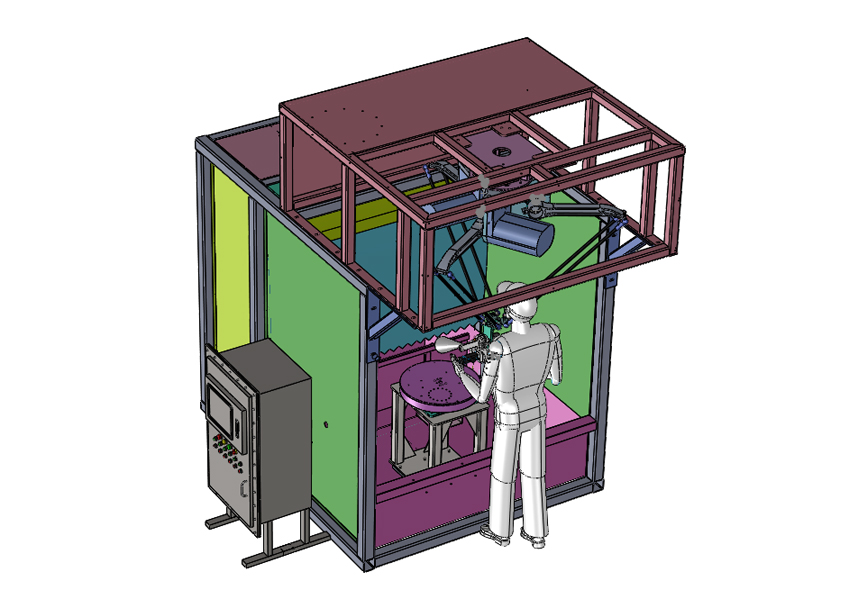

Through our independently developed, high-performance motion control algorithms, dynamics modeling, and bus-based torque control, we achieve Suspended Drag-and-Teach (D&T) functionality. Due to its specialized structure, it is also the lightest and most compliant drag-and-teach robot in China. By utilizing ultra-light suspended control for the teaching and recording process, followed by precision reproduction via motion control, the entire mechanical structure and system have been developed through complete independent innovation.

After three years of refinement, this product has secured a market share exceeding 70% in the ceramic sanitary ware industry and has earned widespread market acclaim.

Application Fields

This product is broadly suitable for the spraying and glazing needs of sanitary ceramics and fixtures, including: toilets (water closets), washbasins, hand basins, squatting pans, mop sinks, urinals, pedestal basins, vanity units, and other related products.