Advantages of Zero-Programming Spraying Robots Over Manual Workers

1. Simple Operation and Quick Mastery

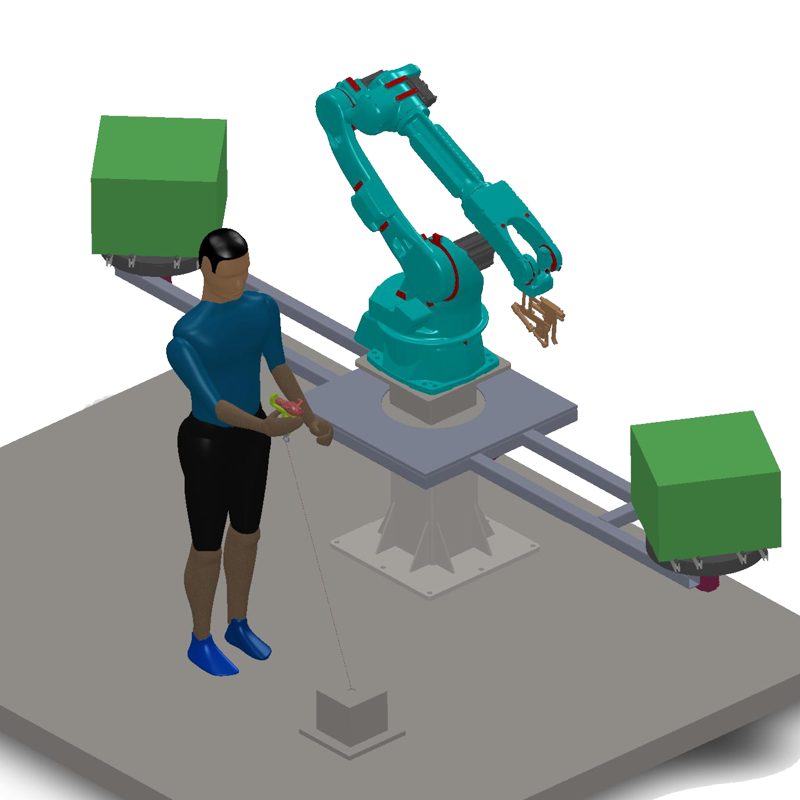

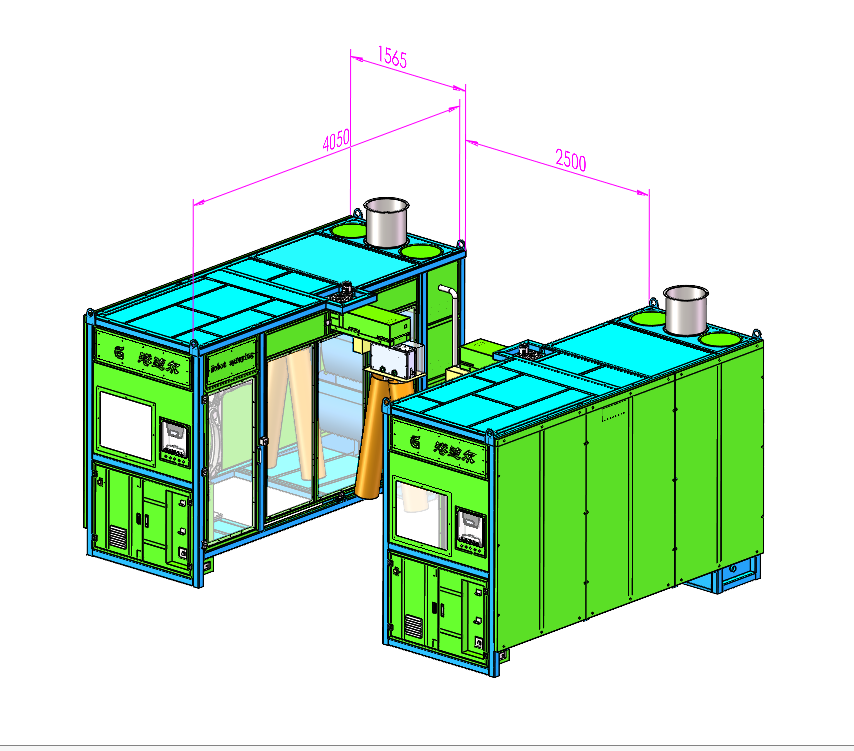

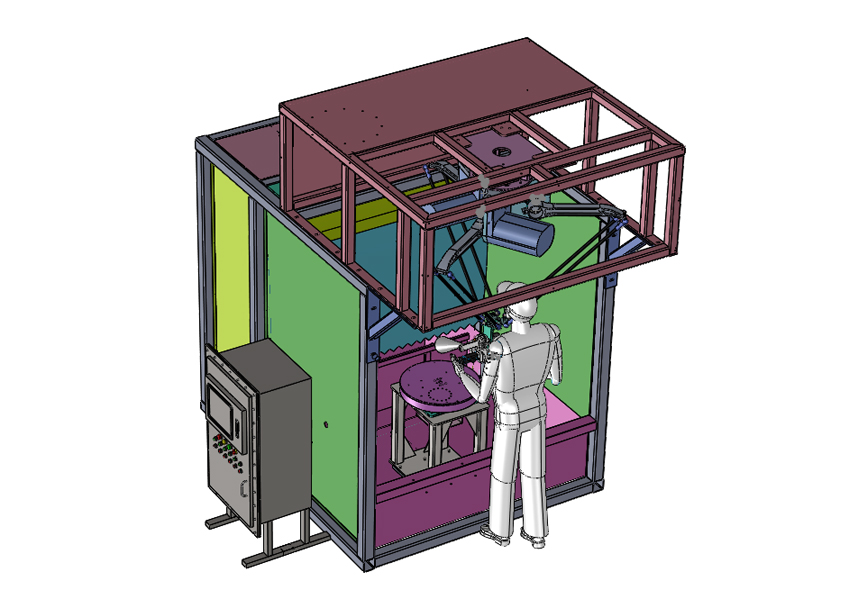

The Zero-Programming Spraying Robot is straightforward to operate, eliminating the need for professional programming knowledge. Utilizing Drag-and-Teach functionality and pre-set programs, operators only need to perform simple setup and adjustments to complete complex spraying tasks. This allows enterprises to quickly deploy the equipment, substantially reducing the time spent on installation and debugging, thus enabling faster production and increased efficiency.

2. Improved Spraying Quality and Efficiency

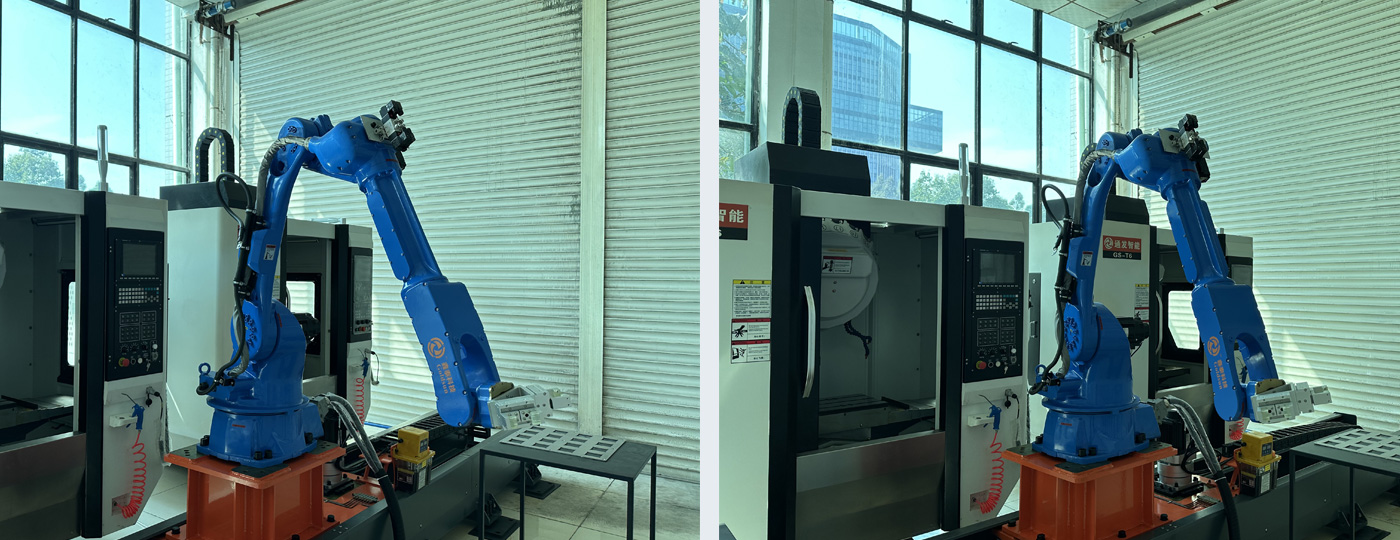

The Zero-Programming Spraying Robot is equipped with an advanced control system that enables precise spraying operations. It can recall the recorded pattern data based on the workpiece's shape and size, ensuring uniform coverage in every corner and achieving automated operation. Simultaneously, the uniformity of the spray reduces material (paint/coating) waste, thereby lowering production costs.

3. High Flexibility and Strong Adaptability

The Zero-Programming Spraying Robot can adapt to workpieces of various shapes and sizes. Whether it's simple full-surface spraying or complex scattered-area treatment, it ensures uniform and precise application. Should spraying parameters or paths require adjustment during production, the operator can simply use the Drag-and-Teach method again, eliminating the need for computer-based programming.