Advanced Code-Free Fiberglass (FRP) Spraying for Industrial Composites

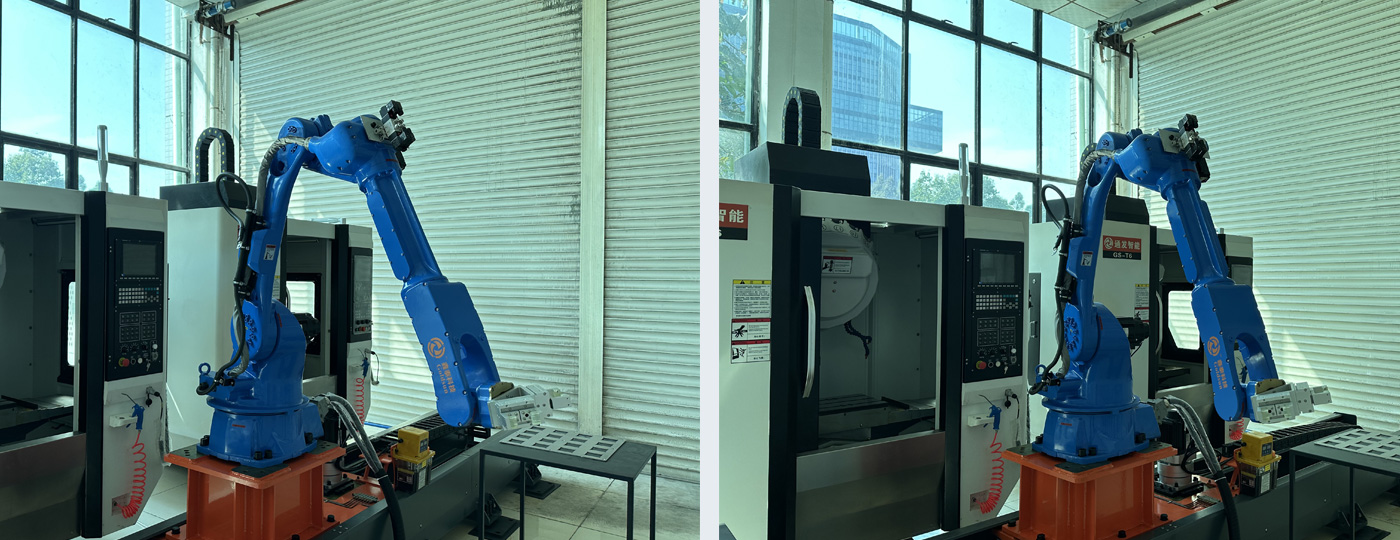

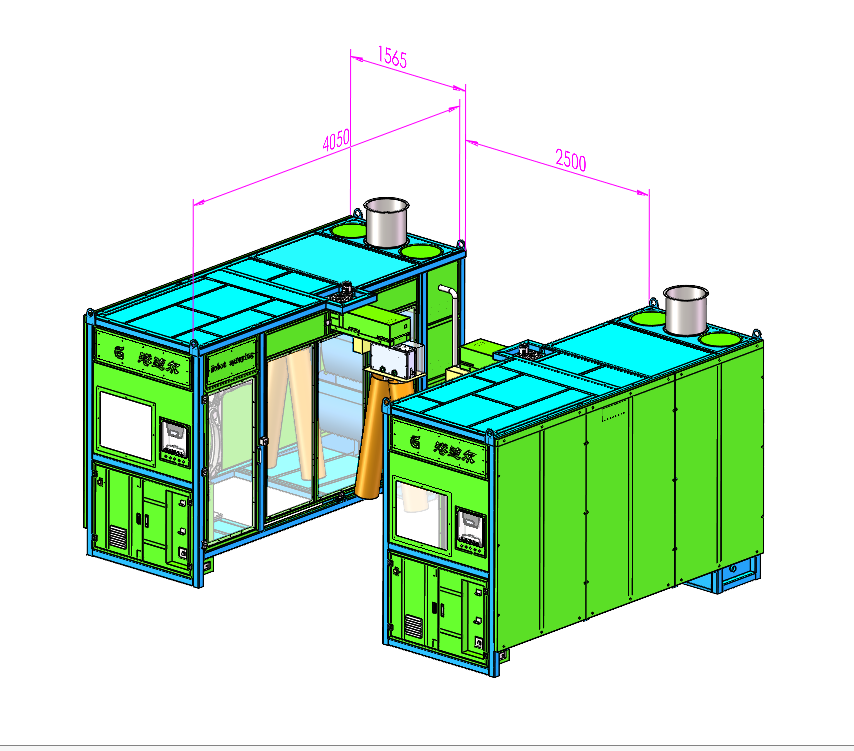

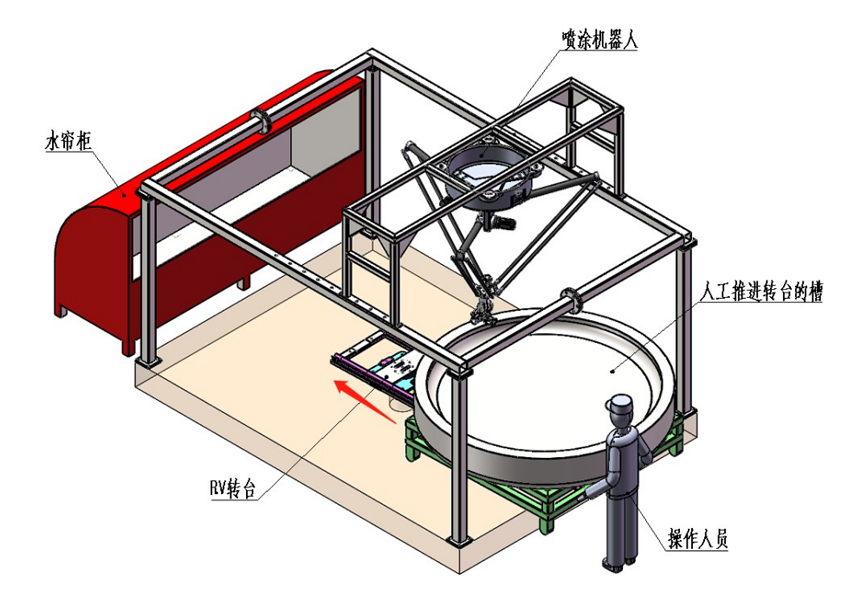

The T2000 Robotic Workstation is the premier domestic solution for Fiberglass Reinforced Plastic (FRP) spraying. Designed by Xinke Intelligence through total independent R&D, this system integrates the robot body, control software, and core hardware into one seamless, high-performance unit.

Why Choose Our FRP Spraying Robot?

Precision and Durability: Specifically engineered for the demanding environments of Cooling Tower and Bathtub manufacturing.

Independent Control System: Built on a Real-time Linux platform with EtherCAT industrial bus communication for lightning-fast response times.

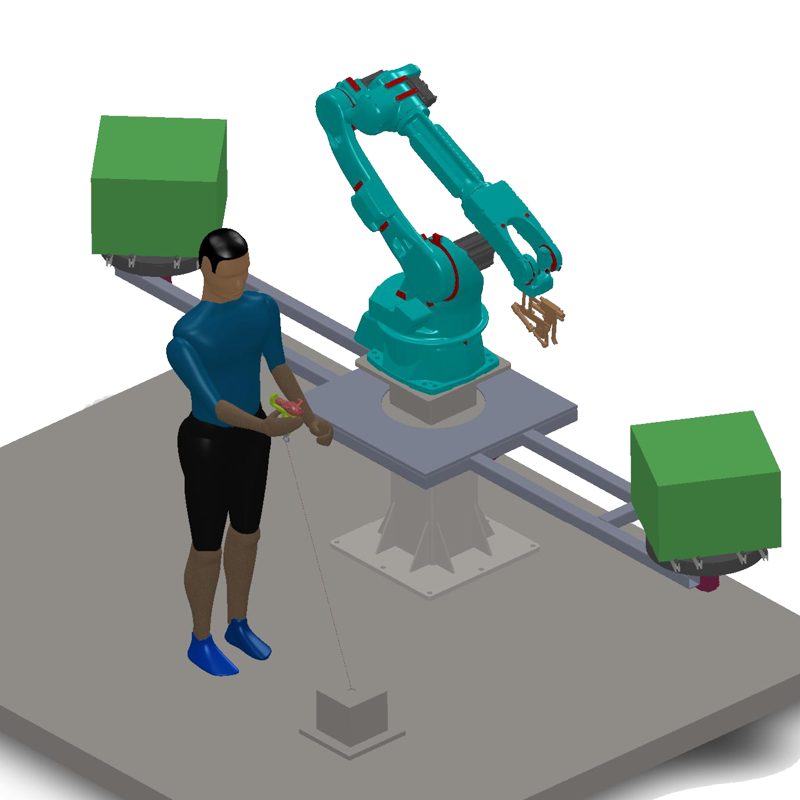

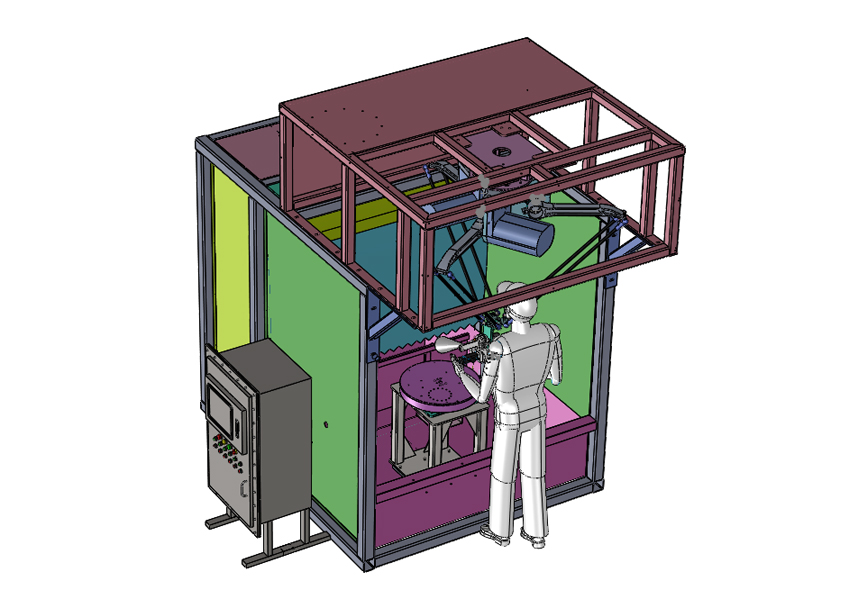

Suspension Drag-and-Teach (D&T): Features the most "gentle" and effortless manual teaching mode in the industry, allowing operators to record complex spray paths without writing a single line of code.

Proprietary High-Performance Algorithms: Utilizes advanced motion control and bus-based torque control to ensure perfect replication of manual spray patterns.

Industrial-Grade Construction: The main cabinet and frame are constructed from fully welded SUS304 stainless steel, and the robot uses high-strength carbon fiber rods for maximum agility and corrosion resistance.