Jeans Spraying Robot: Precision, Efficiency, and Capacity Boost

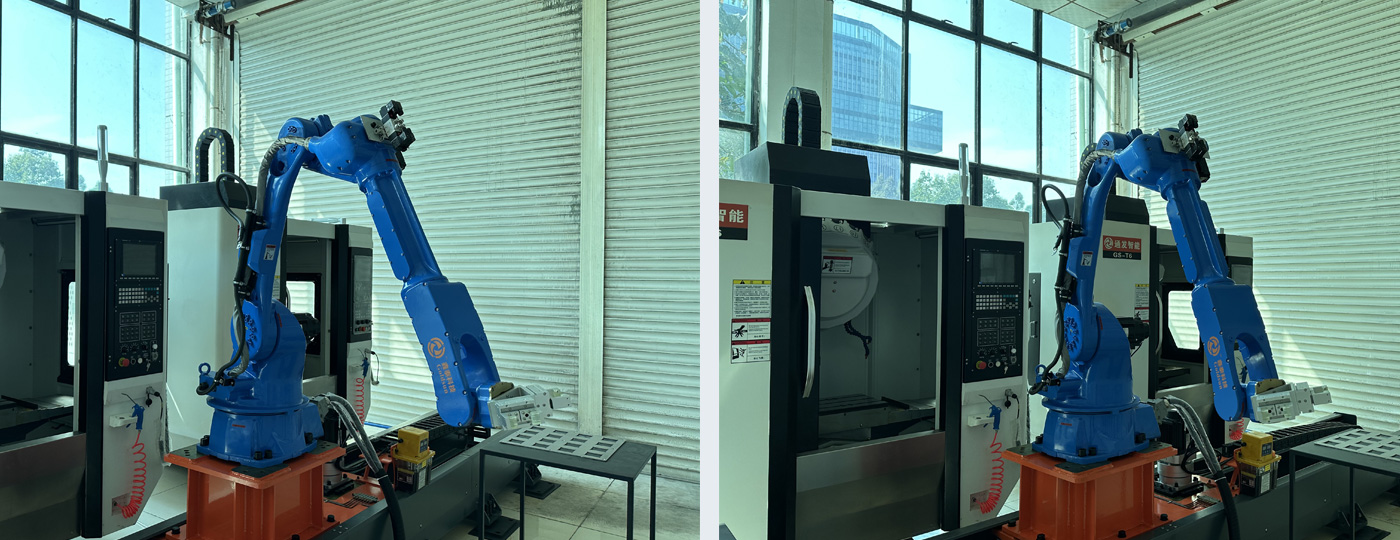

The Jeans Spraying Robot utilizes advanced motion control technology to execute complex spraying tasks with extremely high repeatability. Its operating speed far surpasses manual labor, supporting 24-hour continuous production. This significantly increases production line throughput and equipment utilization, easily meeting the demands of high-volume, fast-paced orders and ensuring timely delivery.

Zero-Programming Workstation: Simple Operation, Lower Entry Barrier

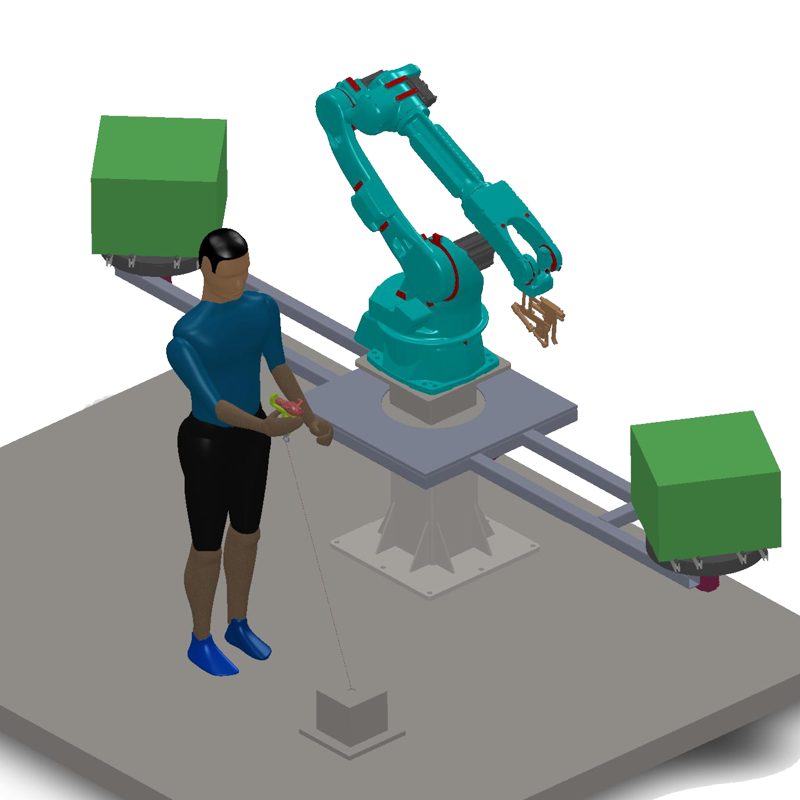

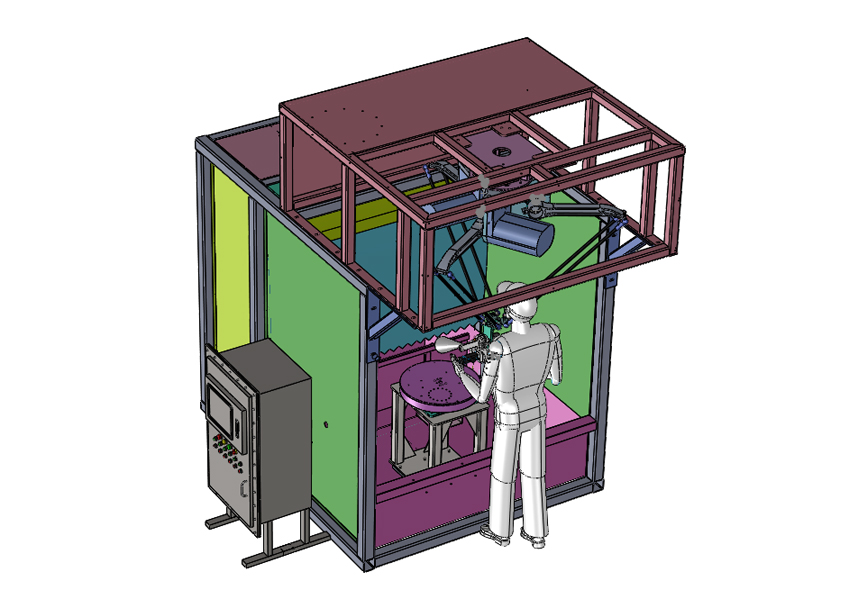

We understand that the convenience of technology application is paramount. The Zero-Programming Spraying Workstation features an intuitive graphical user interface (GUI) and an advanced teaching system, eliminating the need for any professional programming knowledge. Production line personnel can quickly master its use after simple training, easily setting and adjusting various creative patterns. This dramatically lowers the barrier and training costs for businesses introducing automation technology.

Jeans Spraying Robot: Stable Quality, Reduced Waste

Uncontrollable factors in manual spraying often lead to issues like uneven color or pattern defects. The Jeans Spraying Robot uses digital path planning and precise flow control to ensure that every product achieves a uniform, consistent coating with clear boundaries. This significantly improves the first-pass yield and reduces material and cost waste caused by rework and scrap.

Zero-Programming Workstation: Employee Care, Green Manufacturing

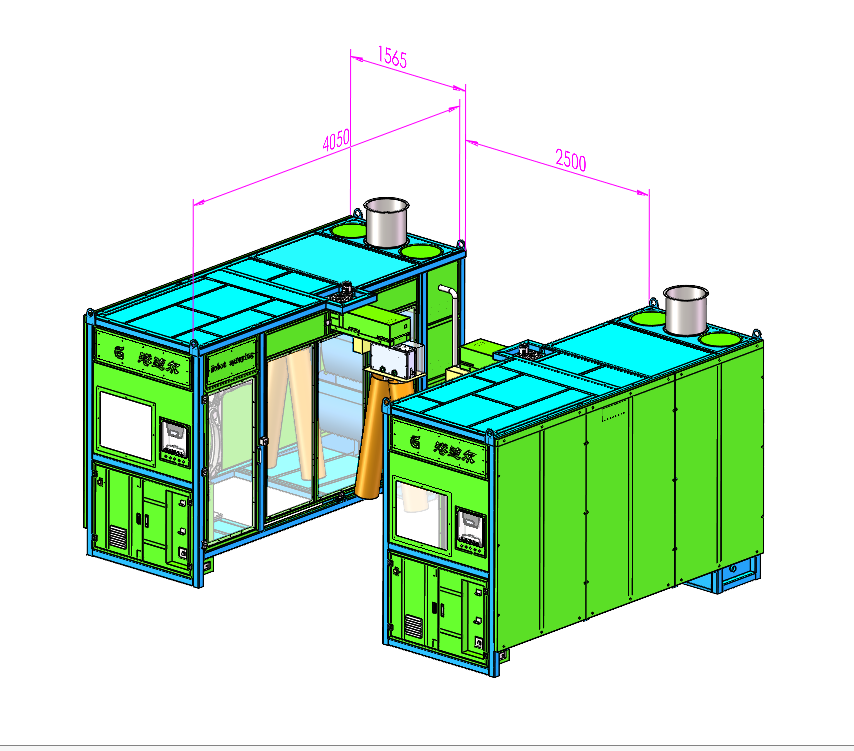

We prioritize employee health. The Zero-Programming Spraying Workstation achieves fully automated, enclosed operation, effectively isolating the operator from the spraying environment. This fundamentally avoids the risk of exposure to paint mist and volatile substances, creating a safer and more comfortable working environment. It is a vital embodiment of a company's commitment to social responsibility and achieving sustainable development.

Investing in the Future: Rapid Return, Long-Term Value

Considering the combined savings in labor costs, the increase in production efficiency, the guarantee of stable quality, and the reduction in material loss, investing in a Zero-Programming Spraying Workstation typically sees a return on investment (ROI) in approximately one year. This is not just a decision to improve current profitability but a strategic investment aimed at building a modern, intelligent factory and securing a long-term competitive advantage.

We are dedicated to driving the upgrading of traditional industries with innovative technology, providing you with intelligent solutions that are not only efficient but also create long-term value. We welcome you to learn more about how our Jeans Spraying Robot can empower your business.

XK Intelligent Manufacturing Company Specializes in (Company Main Products):

Zero-Programming Spraying Robot

Spraying Robot

Automatic Spraying Robot Manufacturer

Jeans Spraying Workstation

Drag-and-Teach Spraying Robot Workstation

Drag-and-Teach Spraying Robot

Automated Spraying Robot

Industrial Spraying Robot

Automated Spraying Equipment

Intelligent Spraying Production Line

Spraying Mechanical Arm (Robotic Arm for Painting)

Spraying Equipment

Various Series of Parallel Robots