Our versatile robotic systems are widely deployed across industries such as Automotive, Home Appliances, Electronics, Computers, Hardware, Plastics, Kitchen & Bath, Lighting, Woodworking, Toys, and Ceramics. This multifunctional robot is a comprehensive solution capable of performing a wide range of surface treatments, including:

Spraying & Painting (Liquid paint and coatings)

Glazing (For ceramic applications)

Adhesive Application (Gluing and bonding)

Powder Coating (Dry finish application)

Sandblasting (Surface preparation and etching)

Cleaning (Industrial surface decontamination)

FRP/Fiberglass Spraying (Fiber-reinforced plastic application)

Multifunctional Robotic Spraying System: Technical Features

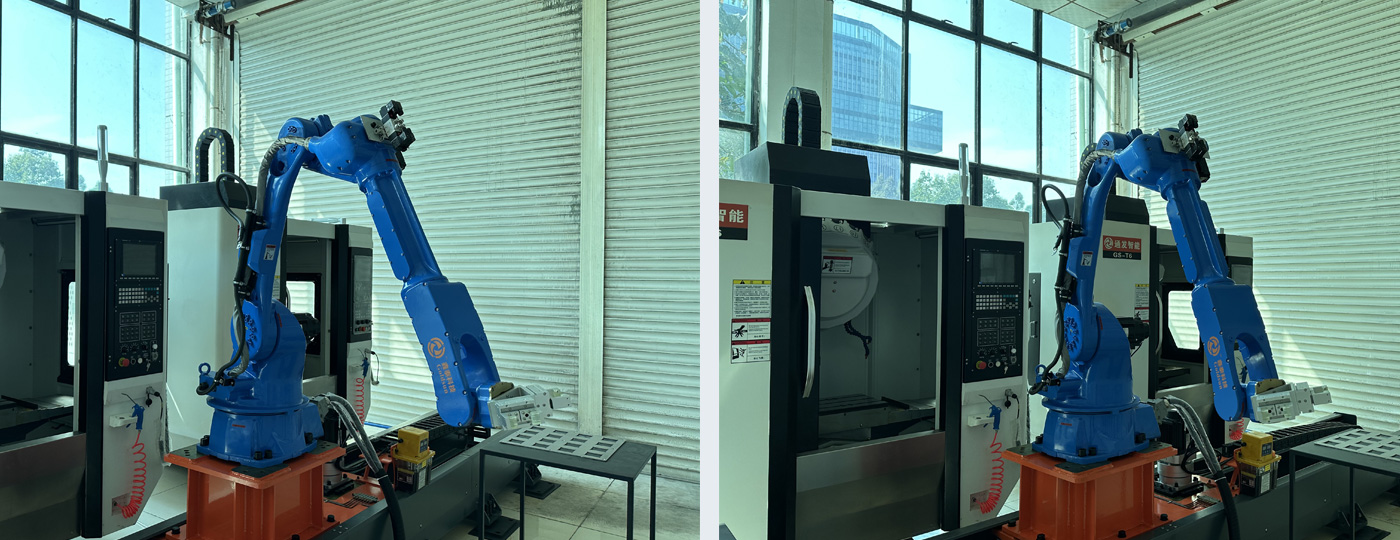

Broad Industry Compatibility: Engineered for diverse manufacturing sectors including Automotive, Home Appliances, Electronics, Hardware, Kitchen & Bath, and Woodworking.

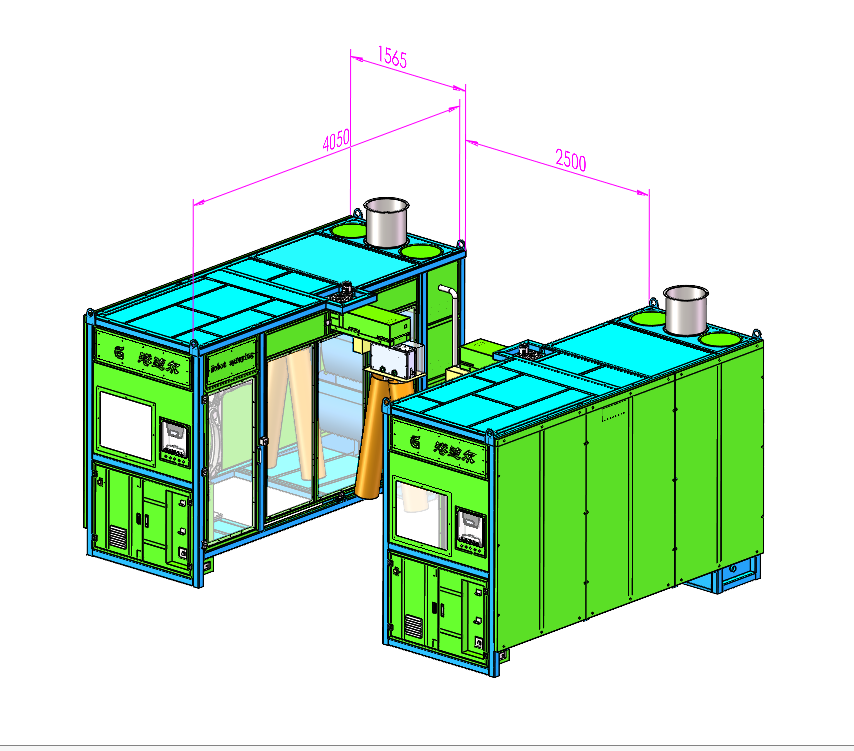

Specialized Panel Processing: Optimized for flat and panel-style workpieces such as furniture tabletops, wardrobe components, and wooden doors.

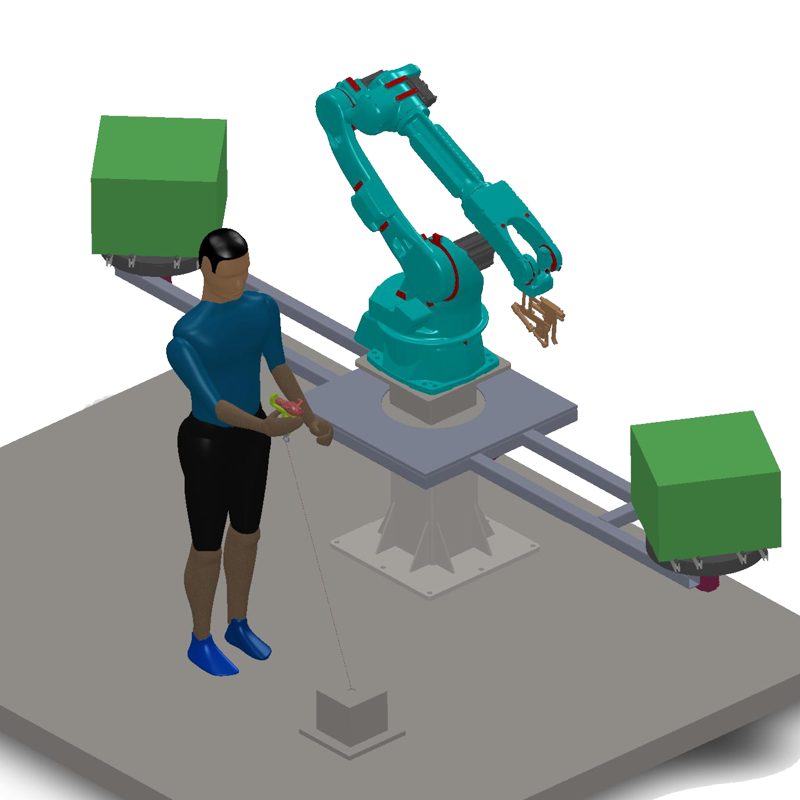

Adaptive Linear Rail: Features an integrated moving track to accommodate products of varying lengths, ensuring seamless automatic spraying operations.

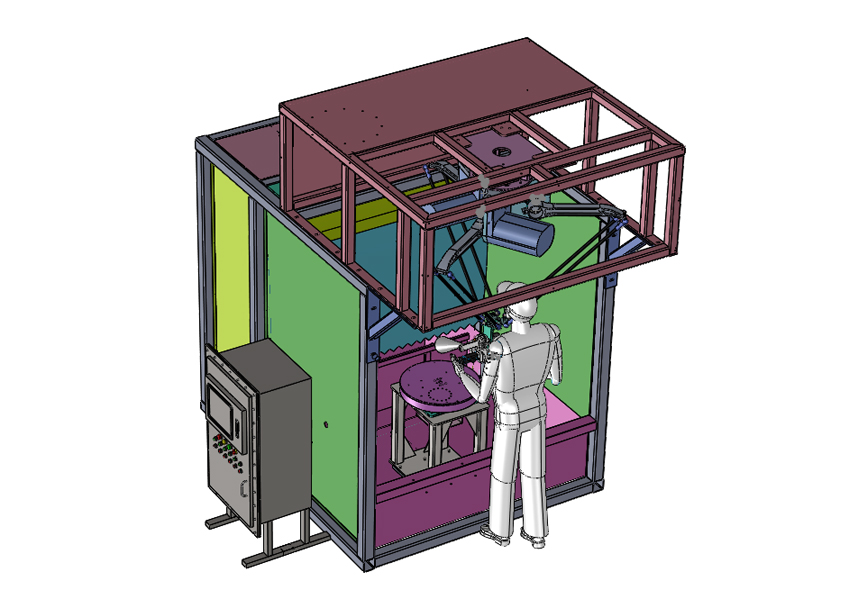

Dynamic Motion Modules: Equipped with an automatic flipping mechanism and a rotating platform to provide 360-degree coverage for complex parts.

Versatile Process Capabilities: A single robotic platform capable of performing liquid painting, ceramic glazing, powder coating, adhesive application, and sandblasting.

Advanced Surface Treatment: Supports specialized industrial tasks including industrial cleaning and fiber-reinforced plastic (FRP) spraying.

High-Mix Batch Production: Designed with flexible configurations to satisfy the requirements of different product batches and frequent style changeovers.