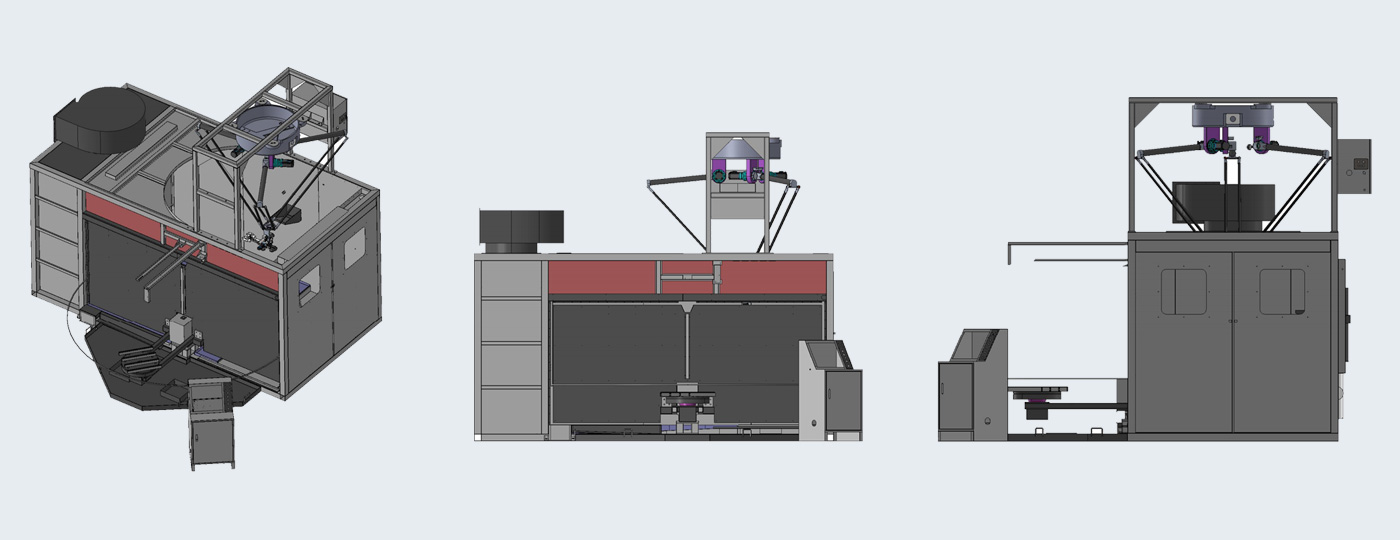

This product represents the largest Parallel-Series Hybrid Structure Robot in China and is a domestic pioneer. The system runs on a Real-Time Linux Operating System and uses the EtherCAT Industrial Bus for communication. Through proprietary high-performance motion control algorithms, advanced dynamics models, and bus-based torque control, it achieves Suspension Drag-and-Teach (Floating Gravity Compensation).

Due to the unique nature of its structure, it is also the lightest and gentlest Drag-and-Teach robot available in China. It utilizes ultra-light suspension control for teaching by demonstration, with the path then precisely reproduced by the motion controller. The entire structure and system are a product of completely independent innovation and development.

NEV Industry Application Fields

The workstation is extensively applied in the NEV industry for various coating tasks, including: adhesive spraying for armrests/center consoles, flocking adhesive and flocking for armrests/center consoles, adhesive spraying and flocking for storage boxes, adhesive spraying and flocking for car door panels, bumper painting, plastic part spraying, and general scattered part painting/top coating.

Flocking Robot Key Features

The Flocking Robot is characterized by the following highlights:

High Efficiency and Stability: The flocking robot utilizes high-precision motion control and a coating system that precisely regulates pressure during the process, ensuring coating uniformity and high yield. Furthermore, the robot can automatically adapt and spray based on different product shapes, guaranteeing spraying precision and effectiveness. The spraying efficiency can reach 99.99%.

Simple Operation: The flocking robot is easy to operate and master, significantly reducing the labor intensity for workers.

High Safety: The robot employs an advanced control system and comprehensive safety protection devices. This ensures high coating quality while effectively preventing workers from accessing hazardous areas, safeguarding personnel safety.

High Reusability/Adaptability: The structural and functional design of the flocking robot allows it to switch between multiple tasks, providing strong adaptability and reusability, which effectively lowers production costs.

Easy to Learn: Basic literacy is sufficient for operation.

Strong Practicality: The Drag-and-Teach programming eliminates the need for professional programming engineers, allowing an operator to become a "programming engineer" in five minutes.

Sterk aanpassingsvermogen: De flockingrobot kan zich aanpassen aan verschillende werkomgevingen en coatingvereisten en voert diverse coatingtaken efficiënt uit.