I. Current Situation: The "Lethal" Traditional Spraying Process

In traditional Ludhiana factories, PP spraying is performed manually on mannequins, leading to several critical issues:

Extreme Occupational Health Risks: Potassium Permanganate is a toxic oxidant. Long-term inhalation causes respiratory damage, lung disease, and skin erosion.

Acute Talent Shortage: The younger generation is unwilling to perform such high-risk labor, leading to a massive drain of skilled technicians.

Quality Instability: Manual spraying is affected by fatigue, resulting in significant Shade Variation, which leads to export rejection rates as high as 5%–8%.

Severe Chemical Waste: Manual spray guns have low atomization efficiency, with roughly 30%–40% of the chemical liquid lost to the air and floor.

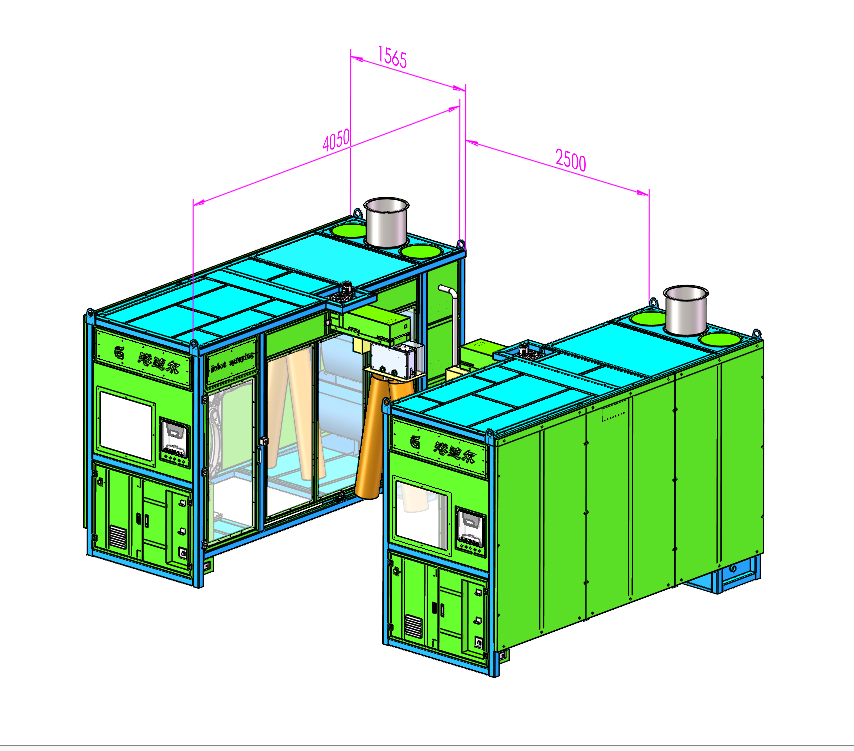

II. The CodeFreeSpray Application Solution

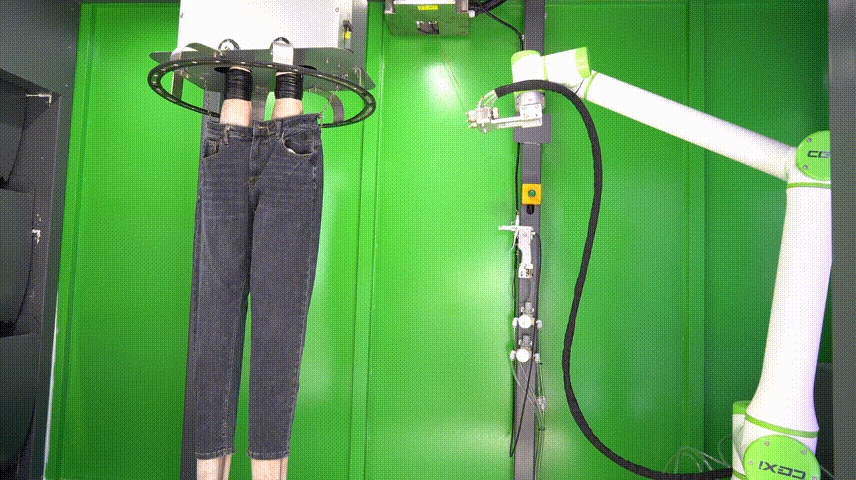

Our CodeFree (No-Programming) Robot is tailored specifically for the denim finishing workflow:

Trajectory Replication: A master laundry technician demonstrates complex paths—such as whiskers (cat-moustaches) and hand-sand effects—to the robot via "Lead-Through Teaching."

360° Synchronization: The robot works in tandem with a rotating mannequin to achieve seamless, full-coverage spraying of the front, back, and side seams.

Multi-Recipe Storage: Switch between different brand styles (e.g., Levi’s, Zara) with one click, requiring zero downtime for debugging.

III. Data Comparison Analysis (Per Production Line/Year)

Based on a mid-sized Ludhiana factory producing 2,000 pairs of jeans per day.

| Dimension | Manual Spraying | CodeFreeSpray Robot | Benefit Variance |

| Spraying Consistency | High fluctuation (Mood/Fatigue) | 100% Digital Replication | 90% reduction in rejection |

| Chemical Utilization | ~60% (High waste) | ~92% (Precision Spraying) | 30% savings on chemicals |

| Output per Hour | 50 – 60 units | 120 – 150 units | 150% efficiency boost |

| Labor Requirement | 6 skilled workers (3 shifts) | 1 general operator | 80% less labor dependency |

| Health/Compliance | Extremely High (Medical/Fines) | Zero occupational risk | Meets Western ESG standards |

IV. Comprehensive Benefits: Why Switch?

Financial Return on Investment (ROI):While labor is relatively cheap in Ludhiana, chemicals (PP and premium resins) are expensive. By reducing chemical waste by 30% and lowering product rejection by 5%, factories typically recover their equipment investment within 10–14 months.

Securing High-End Orders:International buyers (Nike, Adidas, H&M) now mandate transparency and environmental friendliness. Owning a CodeFreeSpray robot is an "entry ticket" into the premium green supply chain.

Digitalizing "Master Experience":A master laundry artisan is the backbone of a Ludhiana factory. With CodeFree technology, you can permanently digitalize their movements. Even if the master retires, their spraying expertise remains in the robot’s chip.

V. Keyword Promotion Strategy (CodeFreeSpray.com)

To build brand awareness in Ludhiana and the global denim market, we recommend focusing on these keywords for SEO and PPC:

Core Keywords:

Denim Spray Robot,PP Spray Automation,Jeans Finishing Robot,No-Code Spraying.Pain Point Keywords:

Potassium Permanganate Spraying Danger,Reduce Denim Rejection Rate,Eco-friendly Denim Finishing.Regional Keywords:

Ludhiana Textile Automation,India Denim Factory Upgrade.

VI. Sample Promotional Copy (Targeting Ludhiana Factory Owners)

"Transform your Ludhiana Denim Factory into a Global Leader!"

Stop wasting expensive chemicals and risking workers' health. CodeFreeSpray.com brings you the first "Teacher-Student" robot for PP spraying.

No Engineers Needed: Your master glazier is the teacher.

30% Chemical Saving: Precise mist control.

Consistent Quality: Zero shade variation for export orders.

Don't just automate. Innovate with CodeFreeSpray.com.