In traditionele fabrieken in Ludhiana wordt het spuiten van PP handmatig uitgevoerd op paspoppen, wat tot verschillende kritieke problemen leidt:

Extreme gezondheidsrisico's op de werkplek: Kaliumpermanganaat is een giftige oxidant. Langdurige inademing veroorzaakt schade aan de luchtwegen, longziekten en huiderosie.

Ernstig tekort aan talent: De jongere generatie is niet bereid dergelijk risicovol werk te verrichten, wat leidt tot een massaal verlies van geschoolde technici.

Kwaliteitsinstabiliteit: Handmatig spuiten wordt beïnvloed door vermoeidheid, wat resulteert in aanzienlijke kleurvariaties en daardoor afkeuringspercentages bij export van wel 5% tot 8% .

Ernstige chemische verspilling: Handmatige spuitpistolen hebben een lage vernevelingsefficiëntie, waardoor ongeveer 30%–40% van de chemische vloeistof in de lucht en op de vloer terechtkomt.

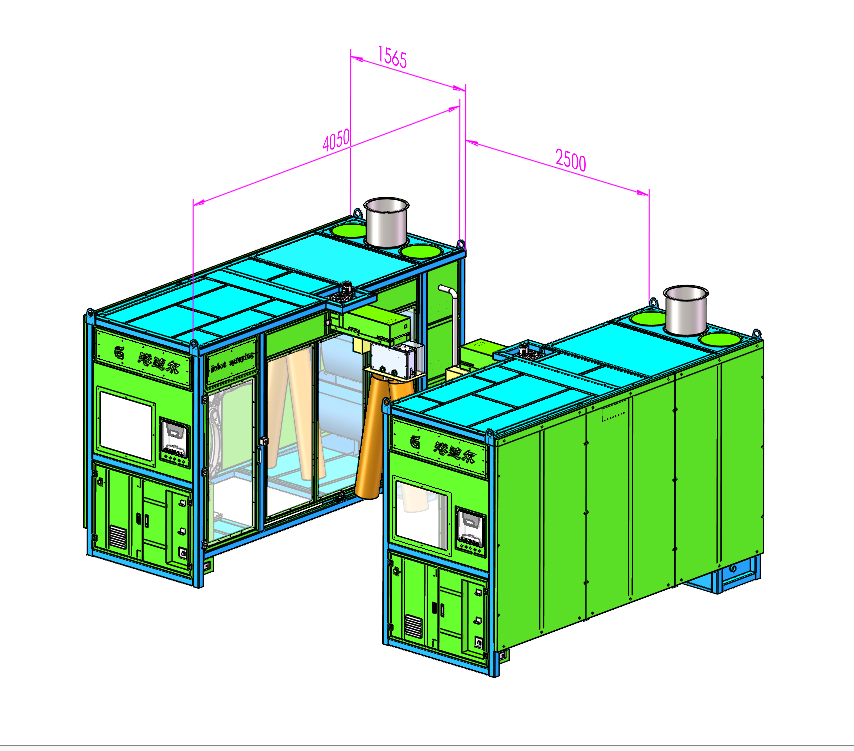

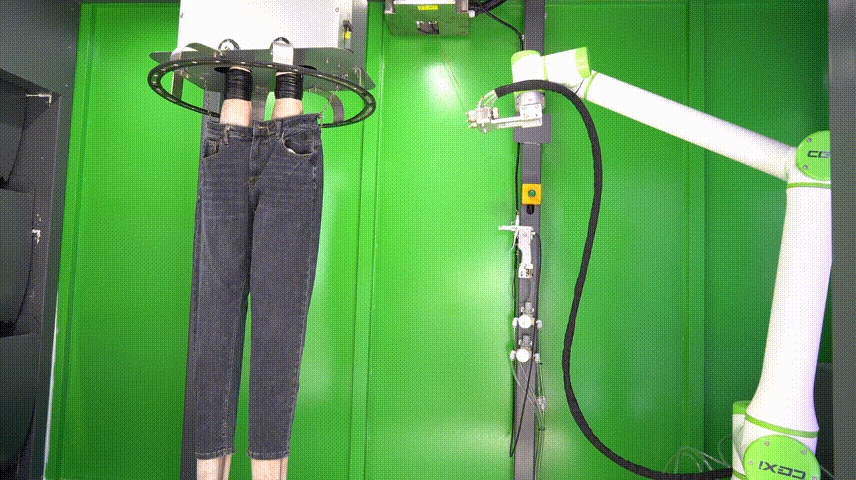

Our CodeFree (No-Programming) Robot is tailored specifically for the denim finishing workflow:

Trajectory Replication: A master laundry technician demonstrates complex paths—such as whiskers (cat-moustaches) and hand-sand effects—to the robot via "Lead-Through Teaching."

360° Synchronization: The robot works in tandem with a rotating mannequin to achieve seamless, full-coverage spraying of the front, back, and side seams.

Multi-Recipe Storage: Switch between different brand styles (e.g., Levi’s, Zara) with one click, requiring zero downtime for debugging.

Based on a mid-sized Ludhiana factory producing 2,000 pairs of jeans per day.

| Dimension | Manual Spraying | CodeFreeSpray Robot | Benefit Variance |

| Spraying Consistency | High fluctuation (Mood/Fatigue) | 100% Digital Replication | 90% reduction in rejection |

| Chemical Utilization | ~60% (High waste) | ~92% (Precision Spraying) | 30% savings on chemicals |

| Output per Hour | 50 – 60 units | 120 – 150 units | 150% efficiency boost |

| Labor Requirement | 6 skilled workers (3 shifts) | 1 general operator | 80% less labor dependency |

| Health/Compliance | Extremely High (Medical/Fines) | Zero occupational risk | Meets Western ESG standards |

Financial Return on Investment (ROI):While labor is relatively cheap in Ludhiana, chemicals (PP and premium resins) are expensive. By reducing chemical waste by 30% and lowering product rejection by 5%, factories typically recover their equipment investment within 10–14 months.

Securing High-End Orders:International buyers (Nike, Adidas, H&M) now mandate transparency and environmental friendliness. Owning a CodeFreeSpray robot is an "entry ticket" into the premium green supply chain.

Digitalizing "Master Experience":A master laundry artisan is the backbone of a Ludhiana factory. With CodeFree technology, you can permanently digitalize their movements. Even if the master retires, their spraying expertise remains in the robot’s chip.

To build brand awareness in Ludhiana and the global denim market, we recommend focusing on these keywords for SEO and PPC:

Core Keywords: Denim Spray Robot, PP Spray Automation, Jeans Finishing Robot, No-Code Spraying.

Pain Point Keywords: Potassium Permanganate Spraying Danger, Reduce Denim Rejection Rate, Eco-friendly Denim Finishing.

Regional Keywords: Ludhiana Textile Automation, India Denim Factory Upgrade.

"Transform your Ludhiana Denim Factory into a Global Leader!"

Stop met het verspillen van dure chemicaliën en het in gevaar brengen van de gezondheid van werknemers. CodeFreeSpray.com presenteert de eerste "leraar-leerling"-robot voor PP-spuiten.

Geen ingenieurs nodig: uw meester-glaszetter is de leraar.

30% besparing op chemicaliën: nauwkeurige nevelregeling.

Constante kwaliteit: geen kleurverschillen voor exportbestellingen.

Automatiseer niet zomaar. Innoveer met CodeFreeSpray.com.