In response to this demand, Guangzhou XK has launched the Zero-Programming Jeans Spraying Workstation, which brings a new revolution to the industry through its comprehensive production optimization capabilities.

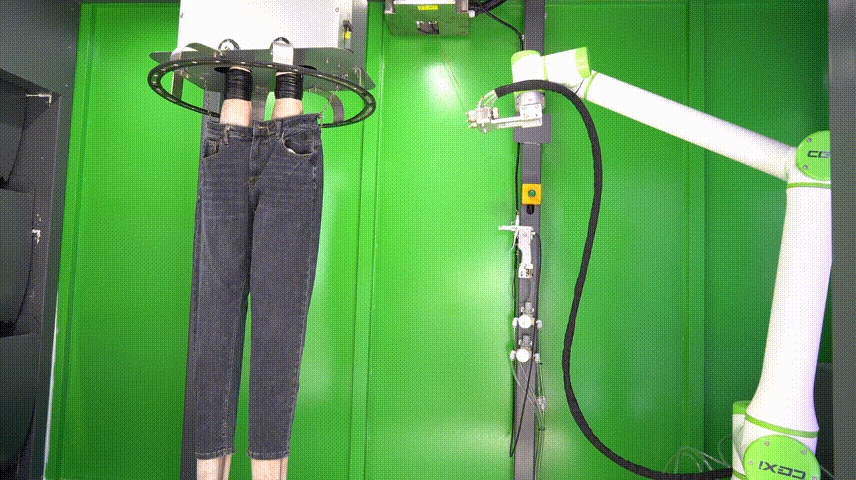

The Zero-Programming Jeans Spraying Workstation is designed around the core philosophy of "simplified operation and enhanced precision." It eliminates complex programming procedures, allowing operators to quickly master the equipment after simple training, which significantly shortens the time required for equipment debugging and deployment. Concurrently, the system can precisely replicate manual spraying trajectories and customize spraying schemes for different parts of the jeans, such as the front and back panels, pockets, and hems, achieving standardized and refined operations. This feature effectively reduces common issues in traditional manual spraying, such as color difference, missed spraying, and uneven thickness, thereby lowering the rework rate and helping enterprises enhance product quality and brand competitiveness.

In terms of production efficiency and cost control, the Zero-Programming Jeans Spraying Workstation demonstrates remarkable advantages. Compared to the limited working hours of human labor, the equipment can operate continuously and stably for 24 hours, easily handling production pressure during peak order periods. Simultaneously, it eliminates significant human labor expenses. Combined with the capacity increase brought by higher efficiency, the enterprise's overall operating costs are substantially reduced, achieving a leap in production benefits.

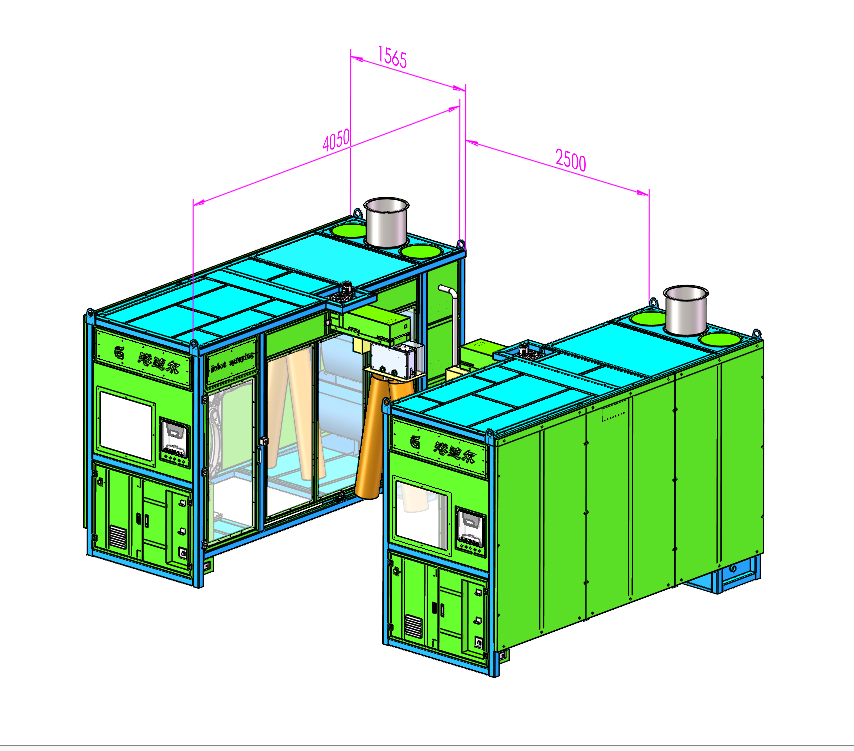

Regarding environmental protection and long-term returns, the Zero-Programming Jeans Spraying Workstation is equipped with a complete ventilation and treatment system. This effectively isolates hazardous substances generated during the spraying process, meets stringent environmental requirements, and creates a safe and healthy working environment for workshop personnel. As a one-time capital investment, the multiple benefits it brings—increased efficiency, labor savings, and reduced rework—help enterprises quickly realize a return on investment. In the long run, it continuously empowers business operations and strengthens development resilience.

Automation and intelligence have become the inevitable trend for the steady development of the denim production industry. The Guangzhou Xinke Zero-Programming Jeans Spraying Workstation, with its pragmatic technical solution, accurately addresses the core pain points of enterprises—such as labor dependence, high costs, efficiency bottlenecks, and safety/environmental compliance—helping them solidify their development foundation and achieve sustainable growth goals in fierce market competition.

Company Main Products:

Zero-Programming Spraying Robot

Spraying Robot

Automatic Spraying Robot Manufacturer

Jeans Spraying Workstation

Drag-and-Teach Spraying Robot Workstation

Drag-and-Teach Spraying Robot

Automated Spraying Robot

Industrial Spraying Robot

Automated Spraying Equipment

Intelligent Spraying Production Line

Spraying Mechanical Arm (Robotic Arm for Painting)

Spraying Equipment

Various Series of Parallel Robots