Strategic Proposal: Scaling Indian Denim Excellence through Robotic Automation

To: The Visionary Leaders of India’s Denim Manufacturing Industry

Subject: Transitioning to Zero-Chemical Impact with Codefree Spray Robots

The Market Context: 2025 and Beyond

The Indian denim sector is no longer just a production engine; it is becoming a global leader in Sustainable Manufacturing. With international brands tightening their "Restricted Substances Lists" (RSL), the traditional use of Potassium Permanganate (PP) is becoming a liability.

Factories in Gujarat and Karnataka that fail to innovate risk losing high-value export contracts. Codefree Spray Robot technology is the solution to this existential challenge.

Why Codefree Spray Robots are the Future for India

1. Solving the "Labor-Quality Gap"

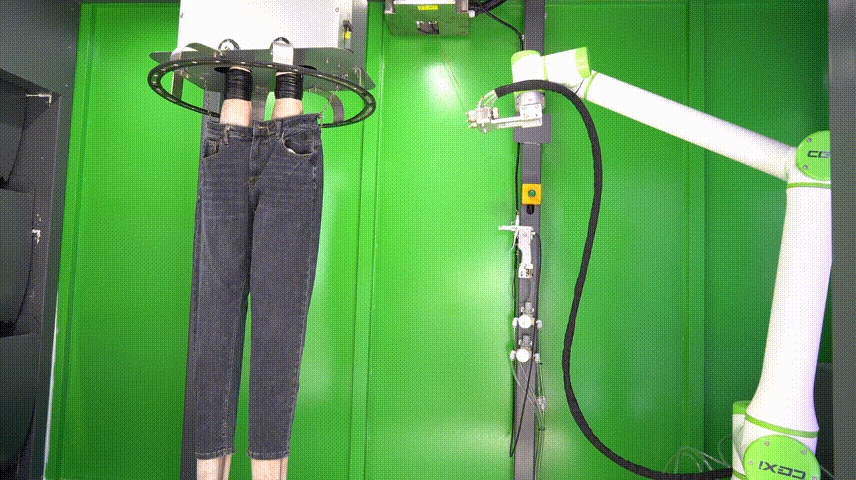

While India has a skilled workforce, manual spraying is inherently inconsistent. A Codefree Spray Robot eliminates human fatigue.

Result: 0% rejection rates due to uneven "whiskering" or "chevrons."

Capacity: Our robots can process 2 to 3 times more garments per hour than a manual operator in a traditional booth.

2. Radical Sustainability (The "Green" ROI)

Water scarcity in industrial zones like Delhi NCR and Erode is a major operational risk.

Zero Neutralization: Since our technology uses eco-safe agents, you bypass the heavy water-rinsing and chemical neutralization (Metabisulfite) steps required by PP.

Effluent Treatment Savings: Reduce the chemical load on your ETP (Effluent Treatment Plant) by up to 60%, significantly lowering your daily operational overhead.

3. Compliance as a Sales Tool

By implementing equipment from codefreespray.com, your factory becomes an "Automatic Green Tier" supplier. This allows you to:

Command premium pricing from European and North American buyers.

Easily pass audits for GOTS (Global Organic Textile Standard) and OEKO-TEX.

Technical Feasibility in the Indian Factory Environment

Our robots are engineered with the "Indian Reality" in mind:

Power Resilience: Built-in surge protection and optimized for energy efficiency to handle fluctuating industrial power grids.

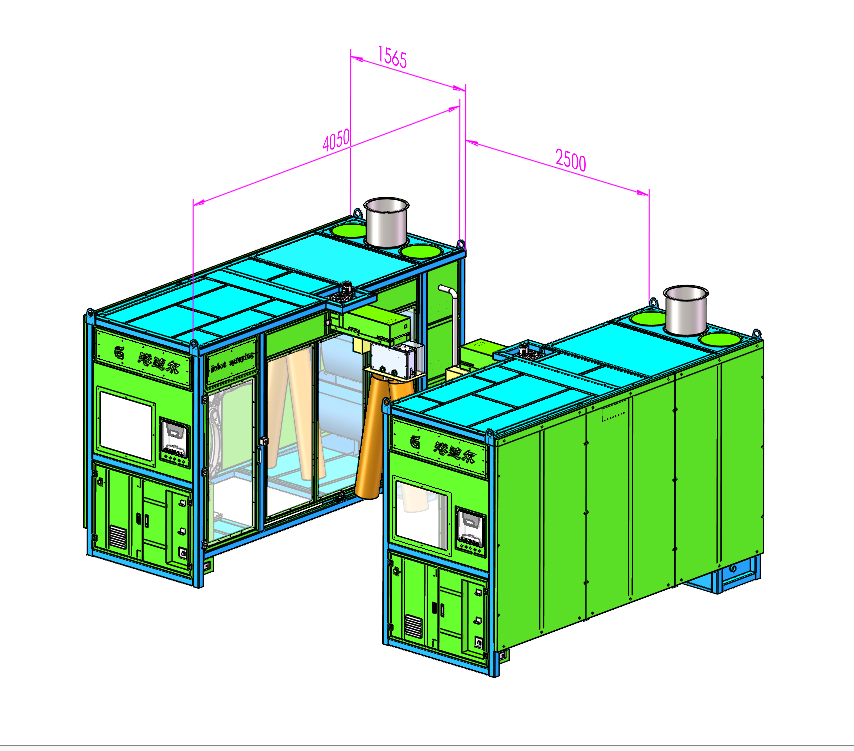

Compact Footprint: Designed to be integrated into existing laundry lines in Mumbai’s space-constrained industrial estates.

Simplified Interface: Operators don't need to be coders; our "Teach-In" software allows a local technician to program a new style in under 5 minutes.

Investment and ROI Analysis

| Metric | Manual PP Spray | Codefree Robot (codefreespray.com) |

| Daily Output | 400 - 600 pcs | 1,200 - 1,800 pcs |

| Health Insurance/Risk | High (Respiratory issues) | Zero |

| Chemical Cost/pc | Increasing (Regulation) | Optimized (Precision Application) |

| Audit Success Rate | 60% (Subjective) | 100% (Systematic) |