Jeans Spraying Robot Debuts at CIIF, Showcasing New Potential for Flexible Manufacturing

At the 2025 China International Industry Fair (CIIF), intelligent manufacturing and flexible production took center stage, demonstrating the new trend toward intelligent and personalized development in industrial automation. The Jeans Spraying Robot, as an innovative solution for the garment manufacturing sector, offers a new pathway for intelligent transformation through its zero-programming technology and automation capabilities. This year's CIIF, themed "New Industrial Quality, Intelligent Manufacturing Without Borders," focused on high-end, intelligent, and green development, attracting over 3,000 exhibitors from 28 countries and regions worldwide and displaying thousands of new technologies and products.

Zero-Programming Workstation Lowers Technical Barrier, Aids SME Upgrades

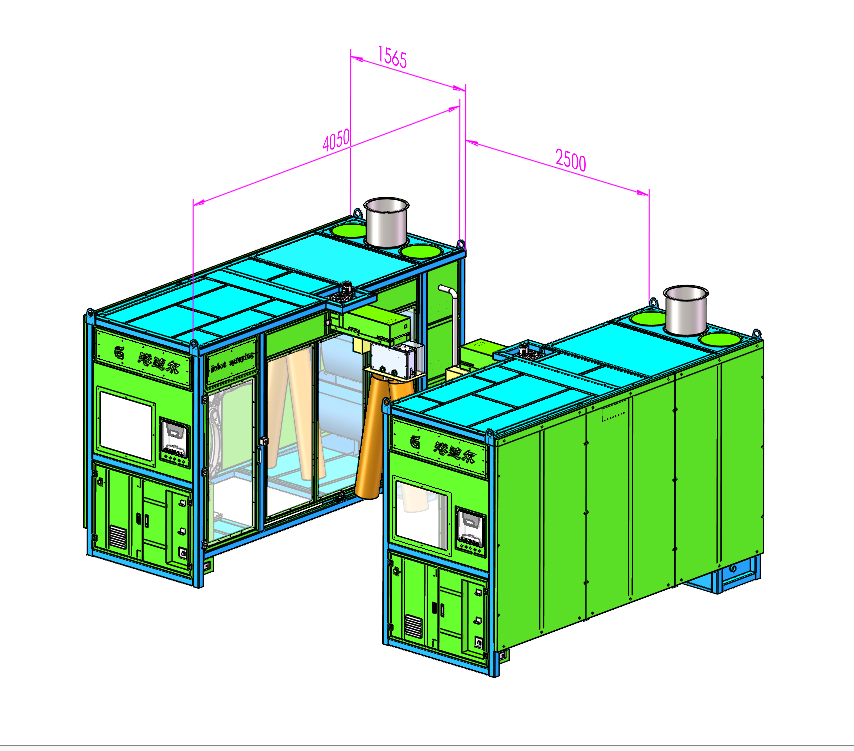

The Zero-Programming Spraying Workstation utilizes a graphical interface and Drag-and-Teach technology, allowing for quick adaptation to production requirements without complex programming. This design significantly lowers the entry barrier for automation technology application. Ordinary workers can operate the system after short-term training, effectively solving the pain point for SMEs who often struggle to "find or afford" professional engineers. On-site at CIIF, this technology received widespread attention for its flexibility and ease of use, reflecting intelligent manufacturing's support for traditional industry upgrading.

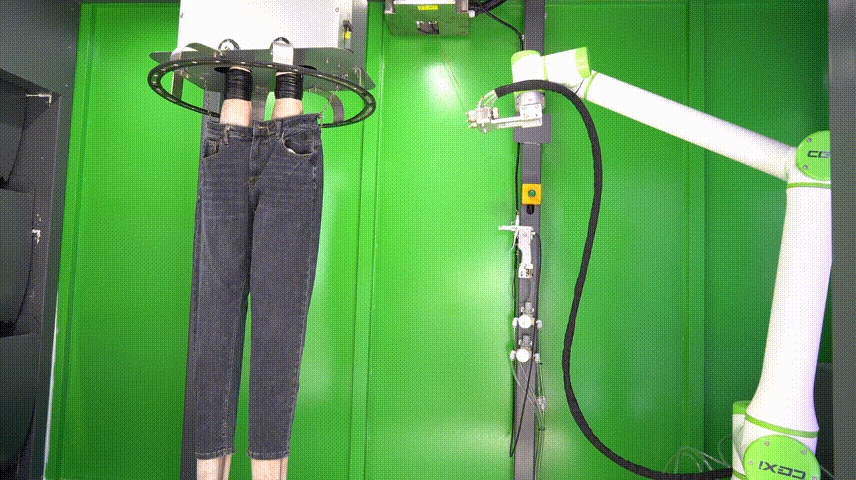

Jeans Spraying Robot Boosts Production Efficiency and Ensures Product Consistency

Through high-precision motion control and 24-hour continuous operation capability, the Jeans Spraying Robot significantly increases output per unit time. Its high repeatability ensures uniform consistency in the spraying thickness and effect of every product, reducing rework and material waste, and helping enterprises stably fulfill orders. The intelligent spraying technology demonstrated at CIIF shows that automated equipment can meet high-quality standards while handling mass production.

Zero-Programming Workstation Supports Small-Batch Customization, Adapting to Market Changes

This CIIF particularly emphasized the value of flexible manufacturing in personalized production. The Zero-Programming Spraying Workstation can rapidly switch spraying patterns and process parameters, easily accommodating the demand for small-batch, multi-variety orders. This flexibility allows denim companies to quickly respond to the growing market need for customized products, enhancing their competitiveness.

Jeans Spraying Robot Improves Working Environment, Practices Green Manufacturing

In traditional spraying operations, workers are exposed to paint mist and chemical volatile substances, posing potential health risks. The Jeans Spraying Robot achieves human-machine separation through fully automated, enclosed operation, effectively safeguarding employee health. Simultaneously, its precise spraying technology reduces coating waste, aligning with the green development concept championed by CIIF.

Zero-Programming Workstation Offers Significant ROI, Empowering Cost Reduction and Efficiency

By saving labor costs, enhancing production efficiency, reducing coating loss, and minimizing defect rates, the Zero-Programming Spraying Workstation typically achieves a return on investment within about one year. Case studies displayed at CIIF indicate that this technology brings long-term stable benefits to enterprises, supporting their sustainable development.

This CIIF clearly demonstrated the practical application of intelligent manufacturing in the garment industry. The technology represented by the Jeans Spraying Robot and the Zero-Programming Spraying Workstation reflects not only the innovation of the equipment itself but also the broader trend of the manufacturing sector toward flexibility, green operation, and digitalization. For apparel companies, the timely introduction of intelligent equipment will be a crucial choice for enhancing competitiveness and adapting to market changes.

Company Main Products:

Zero-Programming Spraying Robot

Zero-Programming Spraying Workstation

Spraying Robot

Automotive Parts Spraying Robot

Automatic Spraying Robot Manufacturer

Drag-and-Teach Spraying Robot Workstation

Drag-and-Teach Spraying Robot

Automated Spraying Robot

Industrial Spraying Robot

Automated Spraying Equipment

Intelligent Spraying Production Line

Spraying Mechanical Arm (Robotic Arm for Painting)

Spraying Equipment

Various Series of Parallel Robots