Application Fields

This product is widely applicable for the glazing and spraying of sanitary ceramics, including toilets, basins, sinks, squatting pans, mop sinks, urinals, pedestal basins, and vanity tops, fully meeting their demanding glazing requirements.

Product Features

Comprehensive Coverage: The spraying area coverage can reach up to 99.9%.

Superior Coating Quality: Through collaborative control, the system ensures consistent and uniform film performance and quality.

High Spraying Efficiency: Capable of 24-hour non-stop operation, ensuring high utilization and efficiency.

Exceptional Durability: Key components are sourced from major industry brands, guaranteeing a service life of 5-6 years or more.

Simple Operation: Requires no professional engineering background; operators can master the basics within 5 minutes.

High Cost-Performance (ROI): The equipment offers fast deployment and high production efficiency, significantly shortening the payback period.

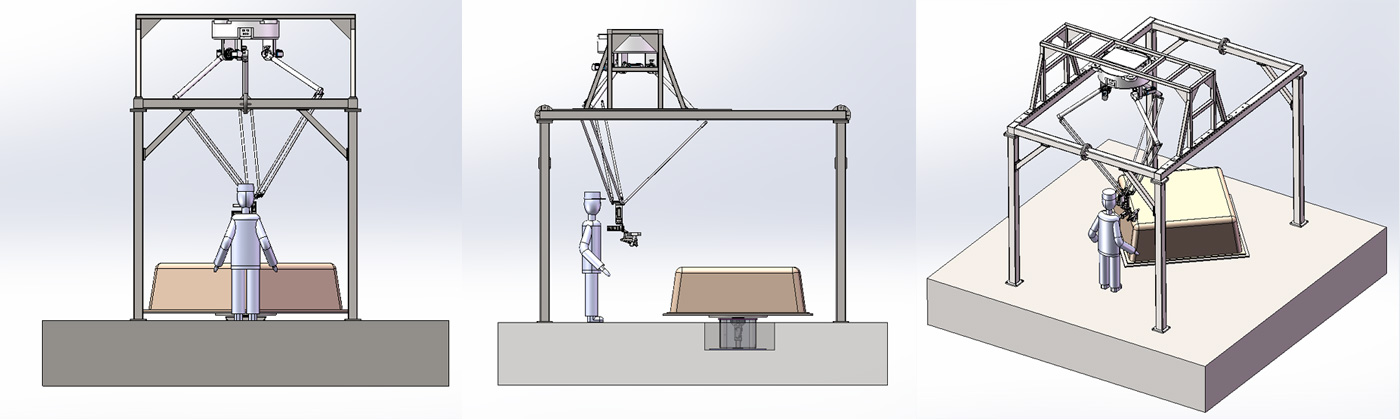

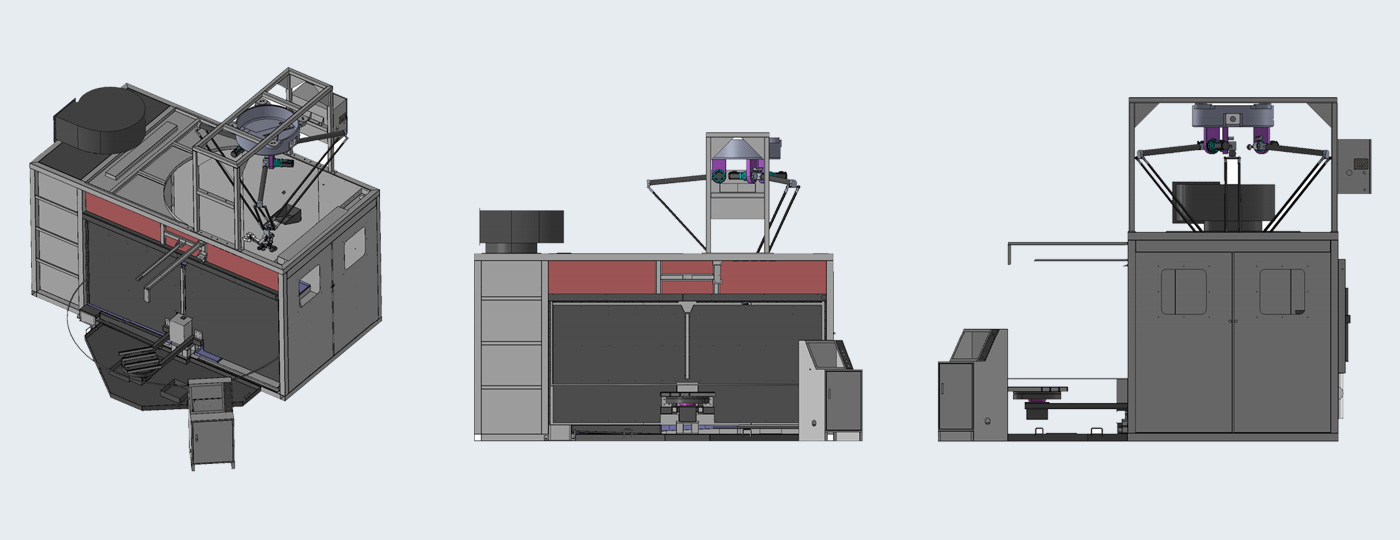

Product Configuration

Component | Specification |

Parallel Robot | Self-manufactured, Carbon Fiber Rod and Servo Motor Combination |

Positioner (Manipulator) | Self-manufactured, RV Reducer, Proprietary Stainless Steel Frame Assembly |

Servo Motors | Motrona |

Robot Reducers | Axis 1/2/3 use Techmag Reducers; Axis 4/5/6 use Harmonic Drive Reducers |

Pneumatic Components | Airtac (Includes cylinders and all associated connectors) |

Cabinet Body | Self-manufactured, Integrated SUS304 Welded Structure |