Product Features

Comprehensive Coverage: The spraying area coverage can reach up to 99.9%.

Superior Coating Quality: Through coordinated control, the system ensures consistent and uniform spraying performance and quality.

High Spraying Efficiency: 24-hour non-stop operation, ensuring high operational efficiency.

Exceptional Durability: Key components are sourced from major industry brands, guaranteeing a service life of 5-6 years or more.

Simple Operation: Requires no professional engineering background; operators can master the basics within 5 minutes.

High Cost-Performance (ROI): The equipment offers fast deployment and high production efficiency, significantly shortening the capital payback period.

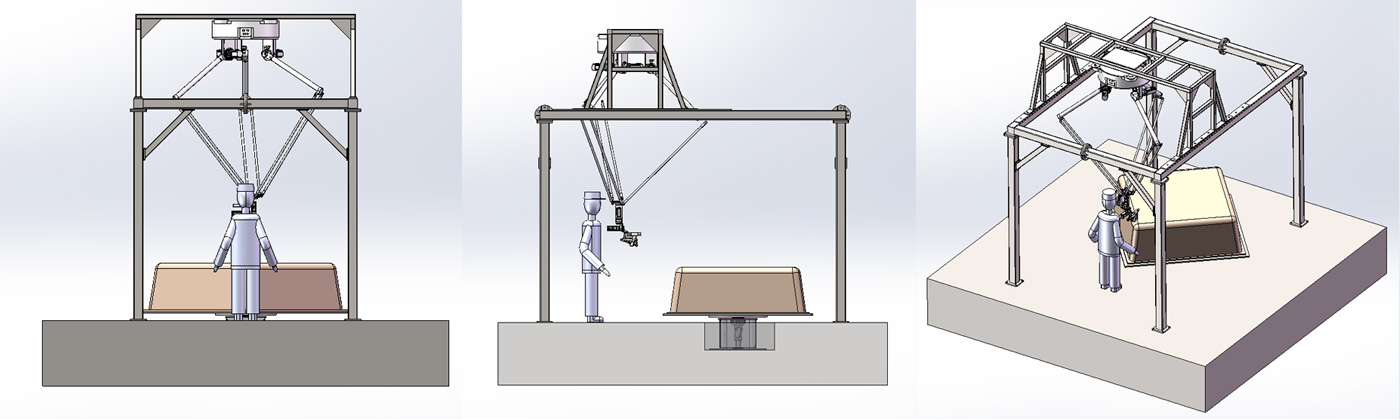

Product Configuration

Component | Specification |

Parallel Robot | Self-manufactured, Carbon Fiber Rod and Servo Motor Combination |

Positioner (Manipulator) | Self-manufactured, RV Reducer, Proprietary Stainless Steel Frame Assembly |

Servo Motors | Motrona |

Robot Reducers | Axis 1/2/3 use Techmag Reducers; Axis 4/5/6 use Harmonic Drive Reducers |

Pneumatic Components | Airtac (Includes cylinders and all associated connectors) |

Cabinet Body | Self-manufactured, Integrated SUS304 Welded Structure |