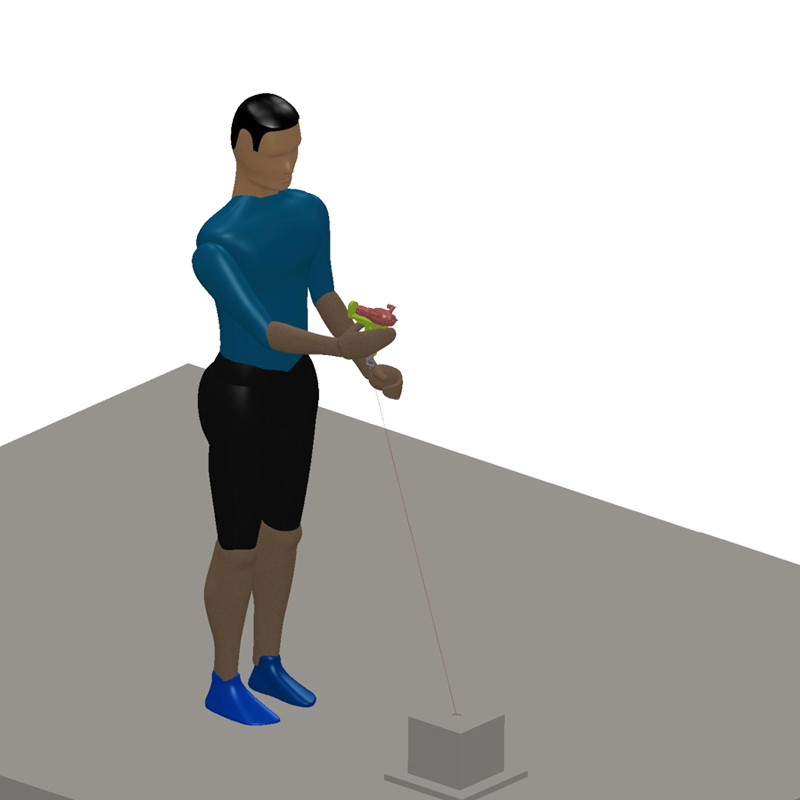

The greatest feature of the Zero-Programming Spraying Robot lies in its ease of use. Operators do not need to master complex computer programming languages; they simply guide the robot arm along the desired path once, and the robot memorizes and executes it autonomously. When spraying hardware parts with complex shapes or hidden surfaces, it can easily handle spraying requirements from various angles, ensuring the completeness of coating coverage. This effectively reduces instances of missed spraying or uneven coating caused by the complex geometry of the workpiece.

From the perspective of economic benefits and production management, deploying the Zero-Programming Spraying Robot brings multiple positive changes to hardware factories. It can adapt to continuous production rhythms and stably execute spraying tasks, helping to improve the overall production line cycle time. Against the backdrop of rising labor costs, the application of this equipment can assist enterprises in more reasonably allocating human resources, liberating workers from repetitive and potentially health-hazardous positions and shifting them to roles such as equipment maintenance or process supervision.

In conclusion, the emergence of Zero-Programming Spraying Robot technology provides a convenient path for automating the spraying processes in the hardware industry and similar sectors. By mimicking and inheriting human skills, it lowers the technical barrier to automation, enabling more factories to explore feasible solutions for improving coating quality and operational efficiency with a relatively small initial investment, thus injecting new vitality into the intelligent upgrading of the manufacturing industry.

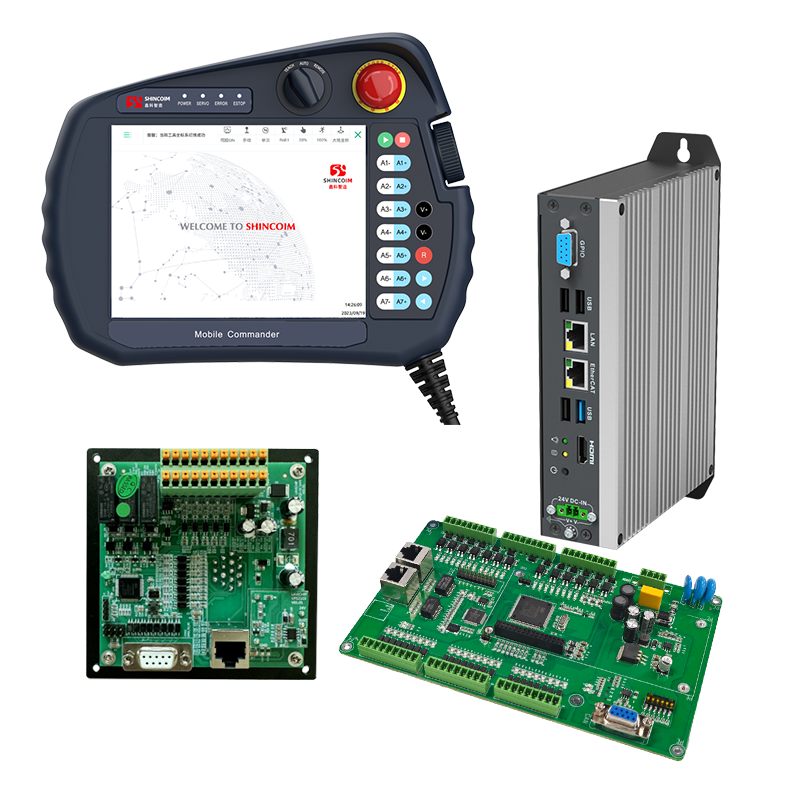

Company Main Products:

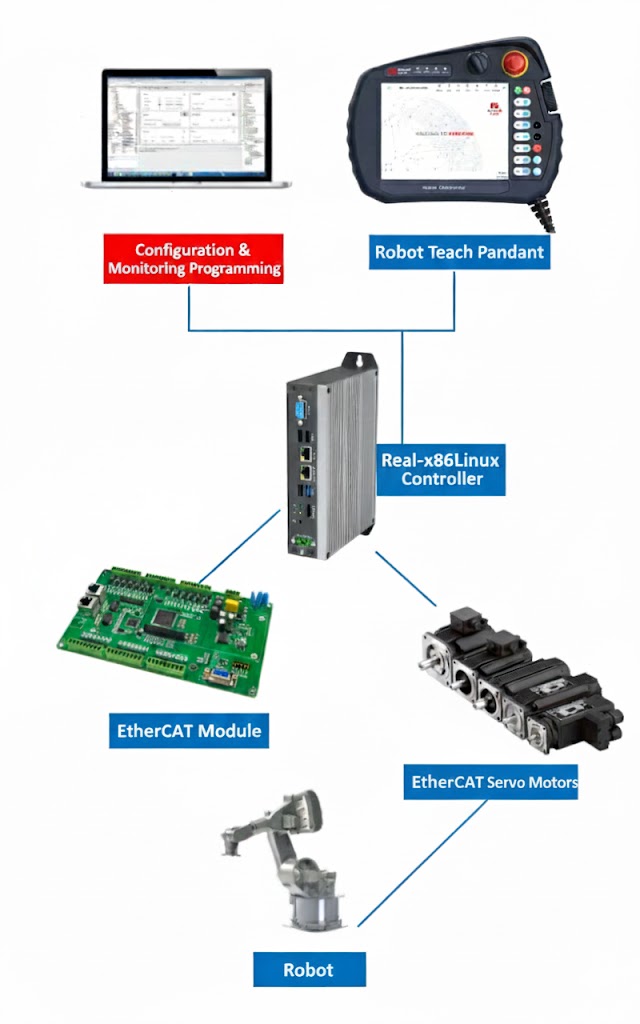

Zero-Programming Spraying Robot

Spraying Robot

Automatic Spraying Robot Manufacturer

Jeans Spraying Workstation

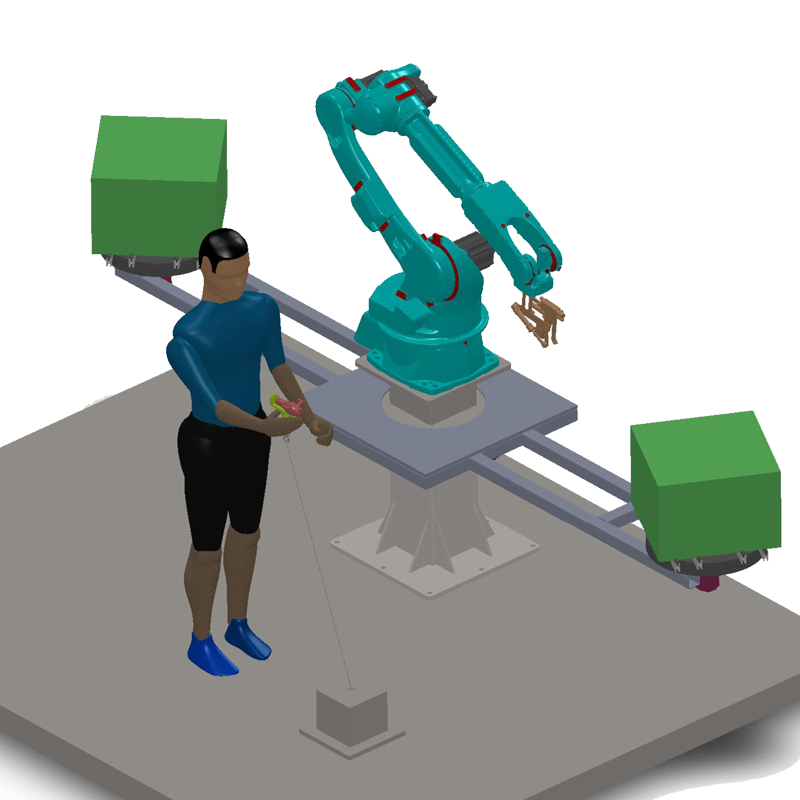

Drag-and-Teach Spraying Robot Workstation

Drag-and-Teach Spraying Robot

Automated Spraying Robot

Industrial Spraying Robot

Automated Spraying Equipment

Intelligent Spraying Production Line

Spraying Mechanical Arm (Robotic Arm for Painting)

Spraying Equipment

Various Series of Parallel Robots