1. Textiles & Apparel

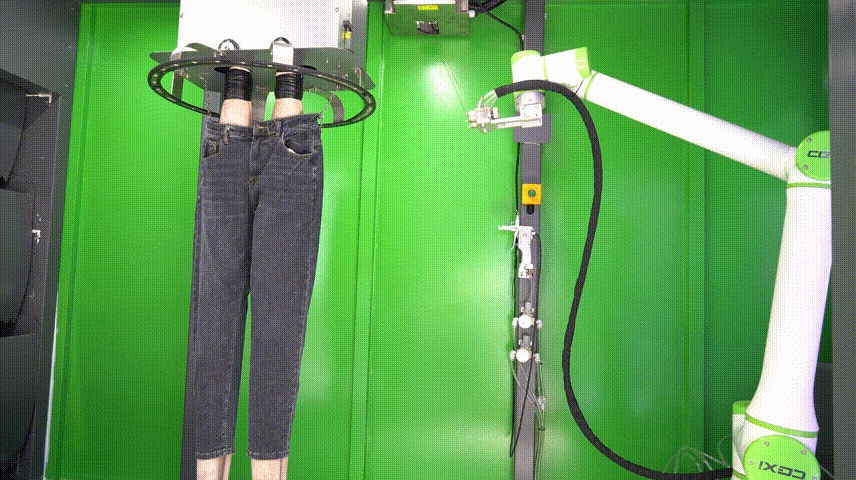

Denim & Jeans Finishing: * "Revolutionize denim finishing with zero-programming robots. Achieve perfect spray effects and whiskering on jeans without complex coding. Visit CodeFreeSpray.com."

Textile Pigment Spraying: * "Automate textile pigment spraying with ease. Our code-free robotic systems ensure consistent dye application and high-speed production for fabric manufacturers."

2. Power & Energy

Instrument Transformer Coating: * "Ensure reliable insulation with zero-programming robotic coating for instrument transformers (CT/VT). High-precision spray solutions for power grid equipment."

Power Utility Equipment Insulation: * "Advanced automated insulation for power utility components. Protect grid infrastructure with uniform, high-performance coatings using code-free robots."

EV Battery Housing Anti-Corrosion: * "Protect EV battery housings from rust with our automated anti-corrosion spraying. Precise, repeatable, and 100% code-free setup for electric vehicle safety."

3. Sanitary Ware & Ceramics

Ceramic Glazing Automation: * "Transform ceramic glazing with zero-programming automation. Achieve flawless, uniform glazes on complex shapes with our intuitive drag-and-teach robots."

Bathtub & Sanitary Ware Spraying: * "Code-free robotic spraying for bathtubs and sanitary ware. Reduce labor costs and improve finish quality with our easy-to-deploy automated glazing systems."

4. Hardware & Metalworking

General Hardware Anti-Rust Coating: * "High-efficiency anti-rust coating for general hardware. Our zero-programming robots provide full coverage for metal parts, ensuring long-lasting protection."

Metal Parts Finishing: * "Automate metal parts finishing without a single line of code. Perfect for high-mix production of brackets, fittings, and industrial hardware components."

Complex Geometry Spraying: * "Solve the challenge of spraying complex geometries. Our drag-and-teach robotic systems handle intricate metal shapes with unmatched precision and zero coding."

5. Automotive Components

Chassis & Underbody Anti-Corrosion: * "Automated anti-corrosion spraying for automotive chassis and underbody parts. Ensure vehicle durability with consistent, code-free protective coating layers."

Automotive Accessory Painting: * "Professional robotic painting for automotive accessories. Achieve premium finishes on car parts with zero-programming automation. Explore CodeFreeSpray.com."